How to Evaluate the Chemical Resistance of HDPE Geomembrane: A Practical Guide for Engineers and Buyers

Time:

Jul 07,2025

How to Evaluate the Chemical Resistance of HDPE Geomembrane: A Practical Guide for Engineers and Buyers

When selecting a geomembrane for your project—especially in landfills, chemical plants, or mining sites—understanding chemical resistance isn’t optional, it’s critical.

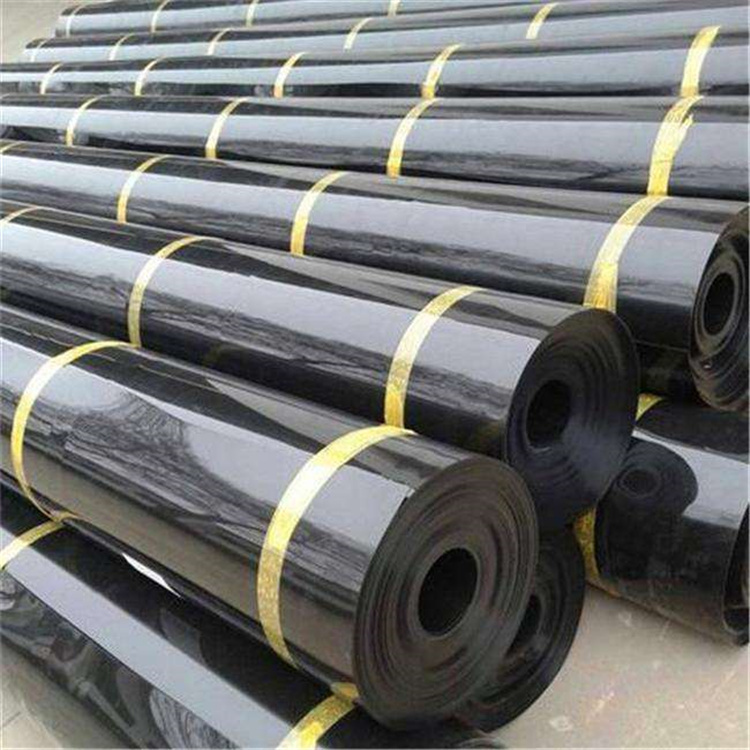

HDPE geomembrane is widely praised for its resistance to a wide range of chemicals. But how do you evaluate whether it’s suitable for your specific environment?

This guide breaks down everything you need to know about evaluating chemical resistance—without needing a chemistry degree.

Why Chemical Resistance Matters

If your HDPE liner is exposed to acids, oils, solvents, or waste leachates, a material failure could mean:

Environmental contamination

Costly clean-up and legal liabilities

Complete project failure

That’s why knowing a liner’s chemical compatibility is essential before installation.

What Makes HDPE Chemically Resistant?

High-density polyethylene (HDPE) is a non-polar, crystalline polymer, meaning it does not easily react with:

Acids and bases

Salts

Alcohols and glycols

Hydrocarbons (e.g., diesel, motor oil)

This makes HDPE suitable for a broad range of industrial applications where other liners might degrade.

3 Steps to Evaluate Chemical Compatibility

✅ Step 1: Check the Manufacturer’s Chemical Resistance Chart

Most reputable manufacturers provide a chemical compatibility guide showing how HDPE performs when exposed to hundreds of substances.

Look for ratings like: Excellent / Good / Fair / Not Recommended

Confirm temperature and concentration ranges

Example:

| Chemical | Resistance | Notes |

|---|---|---|

| Sulfuric Acid (98%) | Excellent | At room temperature |

| Diesel | Excellent | Long-term exposure OK |

| Acetone | Not Recommended | Causes swelling |

✅ Step 2: Review ASTM Test Standards

Ask if the liner has been tested under industry standards such as:

ASTM D543: Chemical resistance by immersion

ASTM D5322: Compatibility with solid waste leachates

GRI-GM13: Includes minimum standards for chemical exposure

These tests involve submerging geomembrane samples in various chemicals for 30 to 90 days to measure physical changes like:

Weight gain or loss

Dimensional stability

Surface cracking

✅ Step 3: Conduct Site-Specific Testing

If your project involves custom or unusual chemicals, it’s best to test the geomembrane with the actual substances used onsite.

Ask your supplier for sample sheets

Immerse in your chemical solution for 7–30 days

Observe for swelling, softening, discoloration, or warping

This real-world test ensures your investment is safe under your specific conditions.

Special Note: Temperature Matters

Chemical resistance is highly temperature-dependent. A substance that’s harmless at 25°C could degrade the liner at 60°C. Always verify compatibility at the maximum operating temperature of your site.

Bonus Tip: Don't Forget the Welds

Even if the membrane resists chemicals, poor welding may compromise the system.

Ensure extrusion or fusion welds also use HDPE material

Ask about chemical compatibility of welding rods and additives

Conclusion: Always Confirm Before You Install

Never assume that “HDPE is always resistant.” While it performs well in most conditions, site-specific verification is the best insurance against future failures.

Work with a supplier who can provide:

Compatibility charts

ASTM-compliant test data

Sample sheets for immersion testing