Fiberglass Geogrid – High-Strength Solution for Soil Reinforcement and Pavement Applications

- Commodity name: Fiberglass Geogrid – High-Strength Solution for Soil Reinforcement and Pavement Applications

Ultra-high temperature resistance

Fatigue crack resistance

Insulation explosion-proof

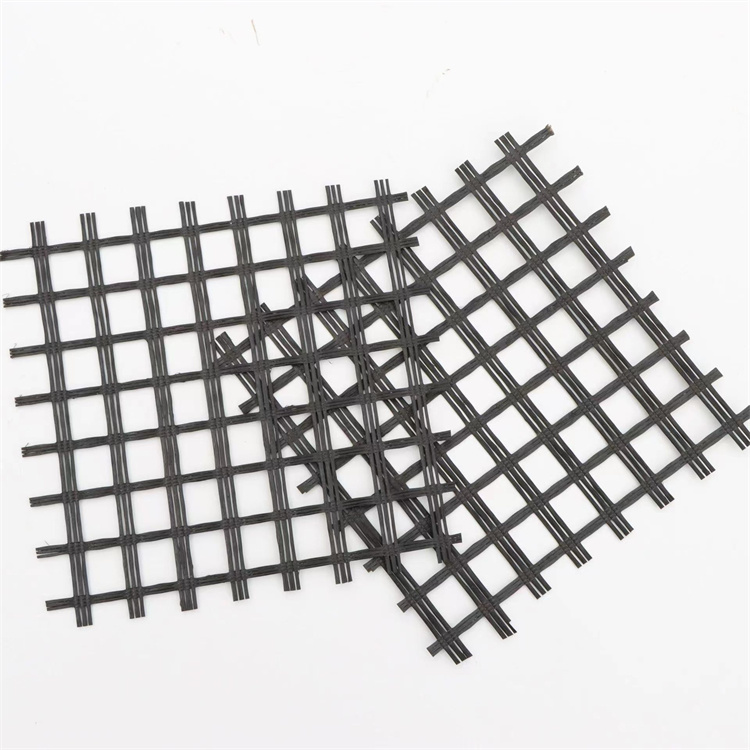

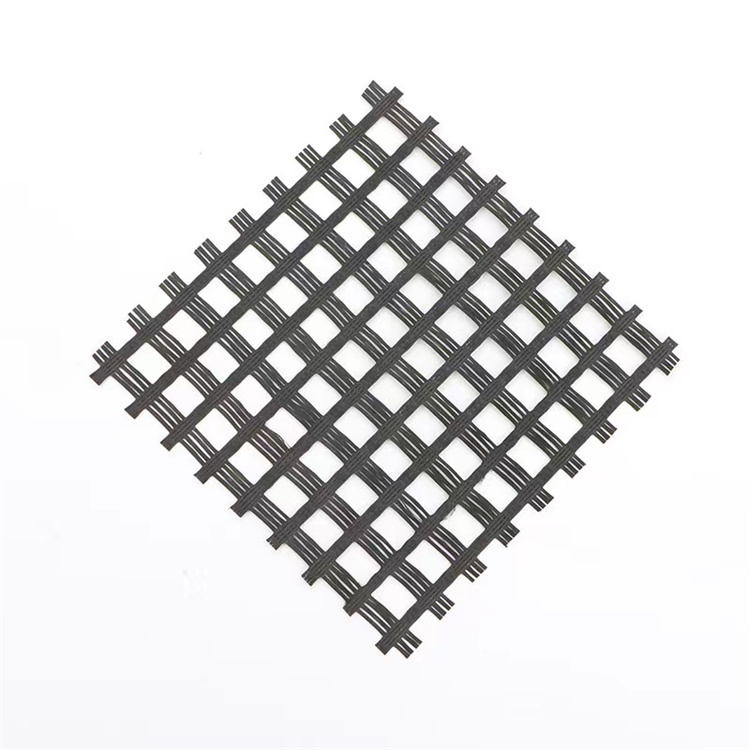

What Is a Fiberglass Geogrid?

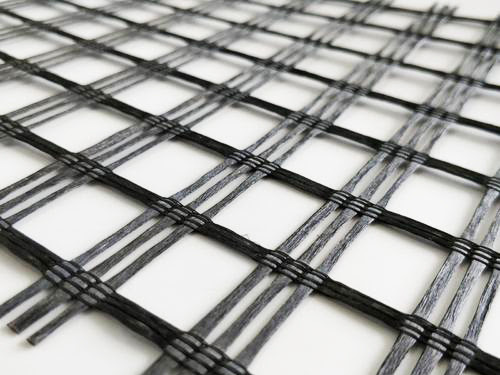

A fiberglass geogrid is a soil reinforcement material made from fiberglass yarns woven or knitted into a grid pattern. It offers high tensile strength, low elongation, and excellent resistance to chemical and environmental degradation.

Fiberglass geogrids are widely used in road construction, pavement reinforcement, retaining walls, and slope stabilization. Their dimensional stability and resistance to UV and alkali make them durable in harsh conditions.

Key Technical Specifications:

-

Material: Fiberglass yarn coated with PVC or other protective resin

-

Tensile Strength: 50–400 kN/m

-

Elongation at Break: ≤ 3%

-

Aperture Size: Typically 10×10 mm to 50×50 mm

-

Thickness: 1.0–3.0 mm

-

Chemical Resistance: Excellent, especially to alkalis and UV

Applications of Fiberglass Geogrids

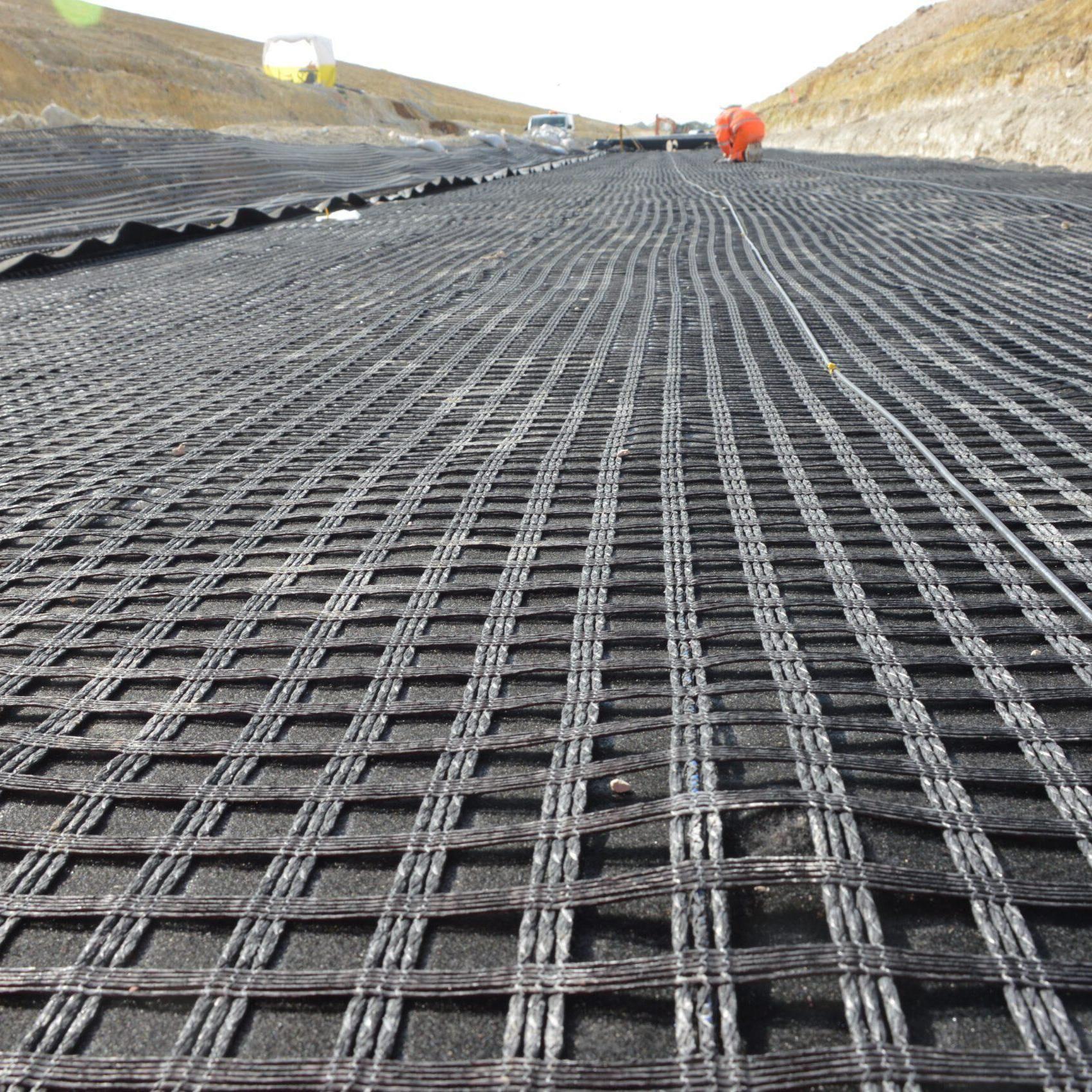

Fiberglass geogrids are widely used in soil reinforcement and stabilization applications for various civil engineering projects. Some of the most common applications include:

Pavement Reinforcement: Reinforces pavement layers and subgrades to prevent cracking and deformation caused by heavy traffic loads.

Road Construction: Provides reinforcement for road foundations and subgrades, improving bearing capacity and extending the lifespan of the road.

Railway Beds: Reinforces railway ballast and subgrade to reduce settlement and ensure long-term track stability.

Embankments: Used for reinforcing embankments and slopes, preventing soil erosion and failure under loads.

Landfills: Provides reinforcement for landfill liners and containment systems, ensuring structural integrity and stability.

Slope Stabilization: Used in slope stabilization projects to reduce the risk of landslides and erosion, especially in areas with high rainfall or steep terrain.

With glass fiber as the base material, it can effectively resist acid, alkali and chemical media erosion and maintain structural integrity in harsh environments. It has excellent tensile strength and deformation resistance, and is not easy to relax under long-term load, providing a long-lasting and stable reinforcement effect.

The material is light and flexible, easy to transport and cut, and can adapt to laying on complex terrain, greatly improving construction efficiency. It can withstand high temperatures and freeze-thaw cycles, has a low coefficient of thermal expansion and contraction, and ensures the long-term stability of the roadbed and pavement under temperature changes.

Looking forward to working with you

Sixteen foreign trade key account managers with more than ten years of engineering experience will promptly respond to any of your engineering questions. What are you waiting for? Let's get started.

Get A Quote

Note: Within a few minutes of filling out the form, you will receive the most timely and effective response.