Steel-Plastic Composite Geogrid – Superior Reinforcement Solution for Soil Stabilization

- Commodity name: Steel-Plastic Composite Geogrid – Superior Reinforcement Solution for Soil Stabilization

Ultra-high tensile strength

Creep resistance

Cold region stability

What is Steel-Plastic Composite Geogrid?

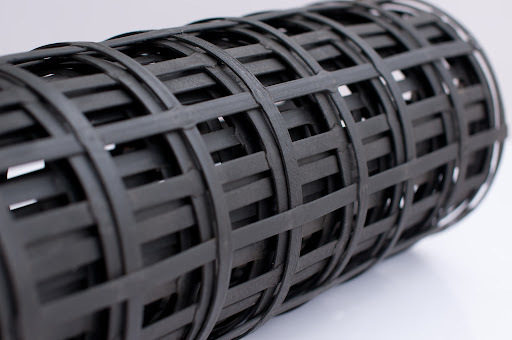

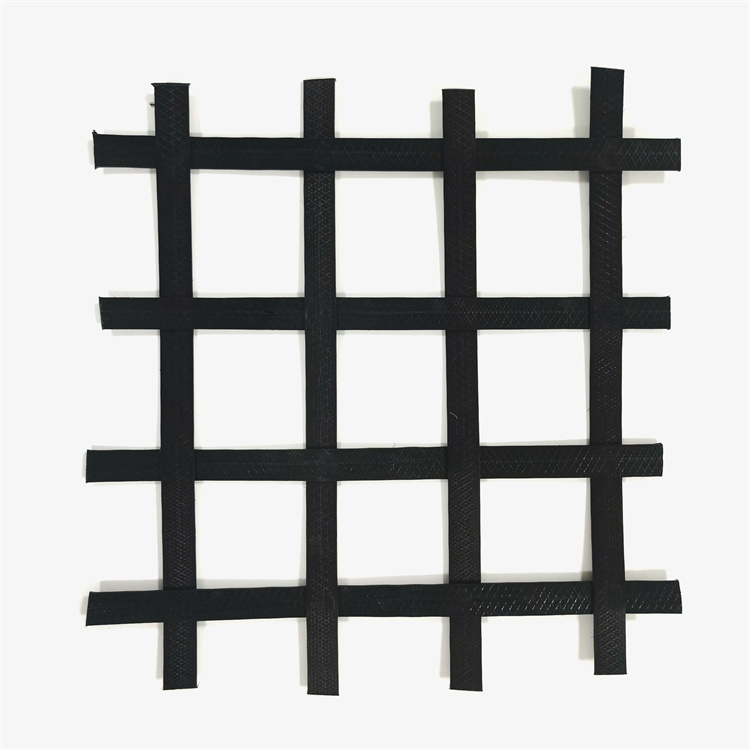

Steel-Plastic Composite Geogrid is a high-strength geosynthetic material made by embedding high tensile steel wires into polyethylene or polypropylene strips, then welding or extruding them into a grid structure. This combination utilizes the rigidity and strength of steel with the corrosion resistance and flexibility of plastic, creating a durable reinforcement material for soil stabilization and structural support. It features excellent tensile strength, low creep, high frictional resistance, and outstanding long-term durability, even under harsh environmental conditions.

Common technical parameters include:

Tensile Strength: Typically from 30kN/m to 150kN/m;

Elongation: ≤3%;

Width: Commonly 1-6 meters;

Anti-corrosion Coating: Bitumen or PE/PP;

Aperture Size: Designed for optimal soil interlocking.

Application of Steel-Plastic Composite Geogrid

Steel-Plastic Composite Geogrid is primarily used in infrastructure projects requiring high load-bearing stability. It is widely applied in highways, railways, retaining walls, bridge abutments, embankments, and soft soil foundations. By reinforcing the subgrade and distributing load evenly, it helps to prevent differential settlement and extend the service life of the structure.

In road construction, it enhances the bearing capacity of weak subgrades, reducing deformation and cracking. For retaining walls and slopes, it provides lateral reinforcement, minimizing the risk of collapse. In landfill and mining applications, it strengthens the foundation and ensures long-term stability under dynamic loads.

Thanks to its resistance to corrosion, it is especially suitable for environments with high moisture or chemical exposure. Installation is simple, and it is compatible with various filling materials like sand, gravel, and clay, making it a cost-effective and efficient solution for soil reinforcement.

It is not afraid of blisters, rust, or salt and alkali corrosion in the soil. It is much stronger than plastic grilles! It can withstand decades of exposure to the sun and freezing in the snow. It is worry-free and can be used for a very long time!

Use it to reinforce retaining walls and build high roadbeds, which can save a lot of stones and earth. Because it is very "supportive" by itself, it can make the filled soil more "united" and stronger. It is rolled up like cloth and can be laid very quickly.

Looking forward to working with you

Sixteen foreign trade key account managers with more than ten years of engineering experience will promptly respond to any of your engineering questions. What are you waiting for? Let's get started.

Get A Quote

Note: Within a few minutes of filling out the form, you will receive the most timely and effective response.