Warp-knitted Polyester Geogrid – Advanced Reinforcement Solution for Soil Stabilization

- Commodity name: Warp-knitted Polyester Geogrid – Advanced Reinforcement Solution for Soil Stabilization

Corrosion resistant and long life

UV resistant

Corrosion resistant

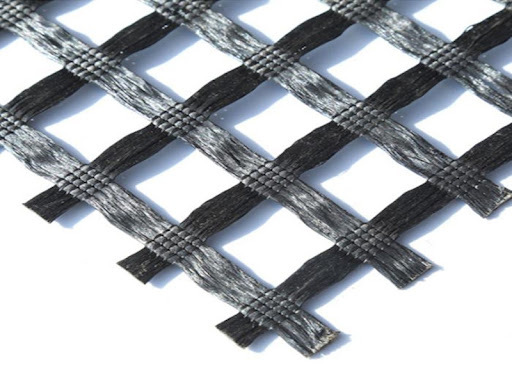

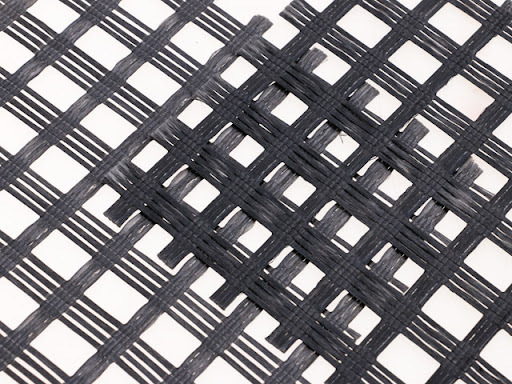

What Is a Warp-Knitted Polyester Geogrid?

A warp-knitted polyester geogrid is a high-strength soil reinforcement material made from polyester (PET) yarns arranged in a grid pattern through warp knitting technology. This process creates a stable, durable geogrid with excellent tensile strength and low elongation.

Warp-knitted polyester geogrids are widely used in retaining walls, road bases, slopes, and embankments. Their strong yarns and knitted structure provide superior load distribution, resistance to creep, and long-term stability.

Key Technical Specifications:

-

Material: High-tenacity polyester (PET) yarn

-

Tensile Strength: 50–1000 kN/m (varies by product)

-

Elongation at Break: ≤ 3%

-

Aperture Size: Customizable, typically 20×20 mm to 50×50 mm

-

Coating: PVC or bitumen coating for UV and chemical protection

-

Thickness: Usually 1.0–4.0 mm

Applications of Warp-knitted Polyester Geogrids

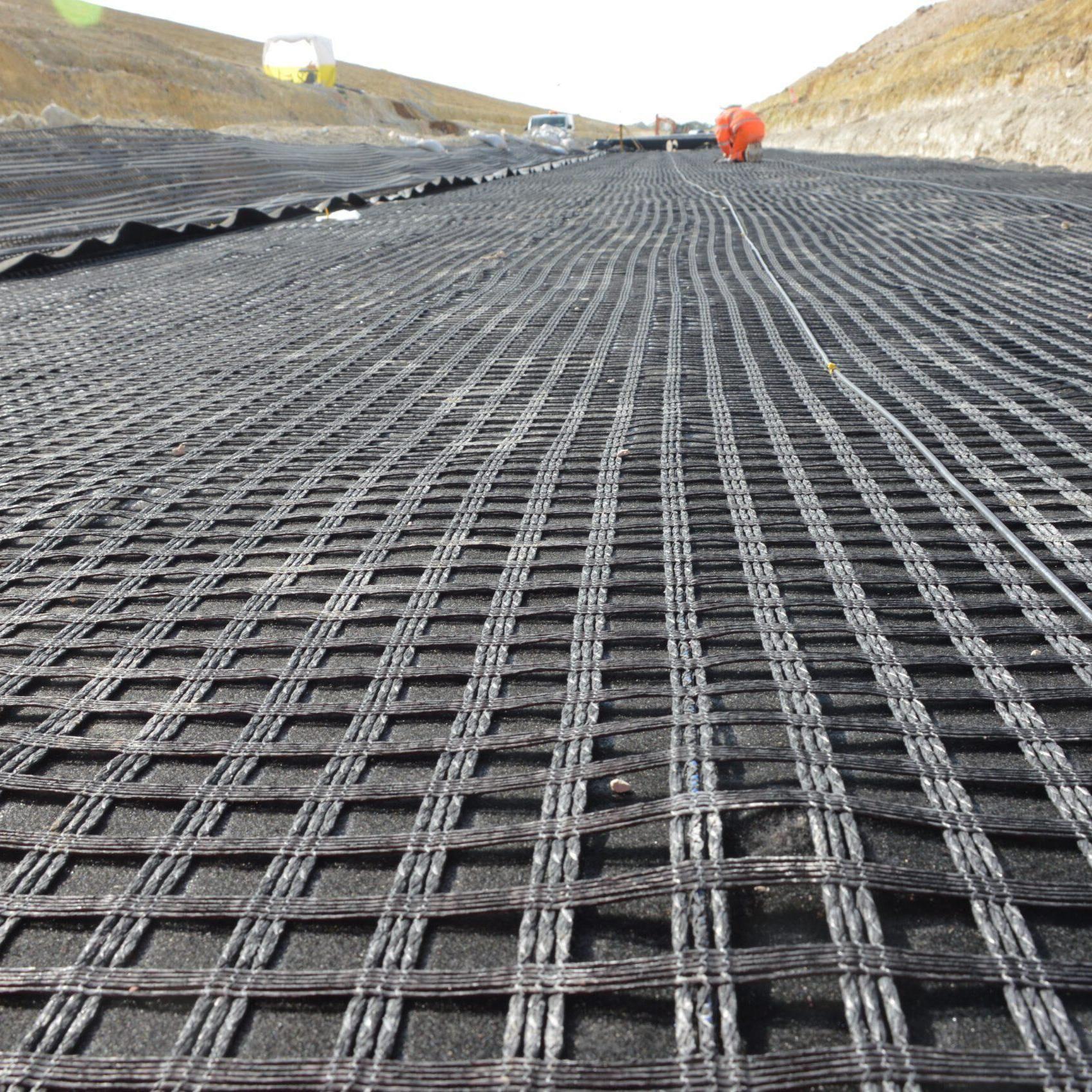

Warp-knitted polyester geogrids are widely used in soil reinforcement and stabilization applications in civil engineering. Some of the primary applications include:

Road Construction: Reinforces road foundations, pavement layers, and subgrades, improving the bearing capacity and long-term performance of roadways.

Railroad Bedding: Provides reinforcement to railway ballast and subgrade, preventing deformation and settlement under heavy rail traffic.

Embankments: Used for reinforcing embankments, ensuring structural stability and preventing soil erosion.

Retaining Walls: Provides additional strength to retaining walls, preventing soil movement and structural failure under heavy loads.

Landfills: Reinforces landfill liners and containment systems, ensuring long-term stability and preventing leachate contamination.

Slope Stabilization: Used to stabilize slopes, providing resistance to sliding and erosion, especially in areas prone to heavy rainfall

The warp knitting process combined with polyester fiber gives it excellent structural stability, strong anti-deformation ability under long-term load, and ensures the long-term stability of the engineering structure. The criss-cross interwoven mesh structure simultaneously improves the directional constraints of the soil, effectively suppresses the lateral displacement and uneven settlement of the fill, and enhances the integrity of the foundation.

Strong corrosion resistance and environmental adaptability

It has outstanding acid and alkali resistance, UV resistance and microbial erosion resistance, and is suitable for harsh environments such as coastal and saline soils to maintain long-term functional integrity. The flexible material is easy to lay and anchor, and adapts to rapid construction in complex terrain; the molecular structure characteristics ensure that it is not easy to relax under repeated loads, reducing maintenance needs.

Looking forward to working with you

Sixteen foreign trade key account managers with more than ten years of engineering experience will promptly respond to any of your engineering questions. What are you waiting for? Let's get started.

Get A Quote

Note: Within a few minutes of filling out the form, you will receive the most timely and effective response.