Composite Geomembrane

- Commodity name: Composite Geomembrane

Corrosion resistance

Good water permeability

Easy construction

What Is a Composite Geomembrane?

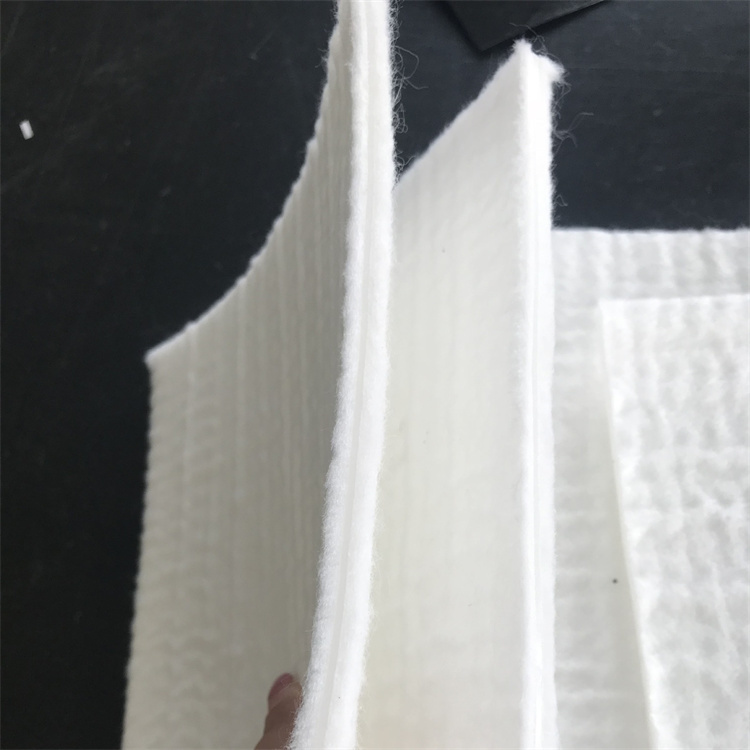

A composite geomembrane is a waterproofing material made by combining a geomembrane (usually HDPE or LDPE) with one or more layers of geotextile through thermal bonding or lamination. This structure improves both impermeability and mechanical strength, making it ideal for harsh engineering environments.

It is commonly used in landfills, reservoirs, sewage treatment, tunnels, mining, and anti-seepage foundations, where both barrier performance and tensile strength are required.

Key Technical Specifications:

-

Structure: 1 layer geomembrane + 1 or 2 layers geotextile

-

Thickness: 0.5–3.0 mm (membrane)

-

Tensile Strength: ≥ 25 kN/m

-

Peel Strength (membrane-geotextile): ≥ 7 N/mm

-

Permeability: ≤ 1.0 × 10⁻¹³ cm/s

Applications of Composite Geomembranes

Composite geomembranes are widely used in industries that require effective seepage control and waterproofing solutions. Some of the most common applications include:

Landfills: Used as a bottom liner and covering material to prevent leachate from contaminating the surrounding soil and groundwater.

Ponds & Reservoirs: Ideal for lining ponds, irrigation reservoirs, and fish farming ponds, preventing water loss and seepage.

Mining: Used in tailings ponds, leach pads, and containment facilities to ensure hazardous substances are contained and water seepage is controlled.

Oil & Gas: Applied in containment ponds, spill areas, and chemical storage sites to protect against hazardous spills and leaks.

Agriculture: Used in irrigation channels, agricultural reservoirs, and ponds, offering long-lasting waterproofing and preventing water wastage.

Construction: Employed for foundation waterproofing, underground tunnels, and building basements, providing effective moisture control.

Geomembrane forms the ultimate watertight defense line. Whether it is the bottom of a reservoir, a landfill or a chemical park, it silently takes root, locking the water flow invisibly and making leakage a thing of the past.

It does not become brittle when burned by the scorching sun, does not crack when frozen in extreme cold, and does not corrode when corroded by strong acids. It is the "Transformer" of the engineering industry, and it holds its anti-seepage position amidst subsidence and distortion

Looking forward to working with you

Sixteen foreign trade key account managers with more than ten years of engineering experience will promptly respond to any of your engineering questions. What are you waiting for? Let's get started.

Get A Quote

Note: Within a few minutes of filling out the form, you will receive the most timely and effective response.