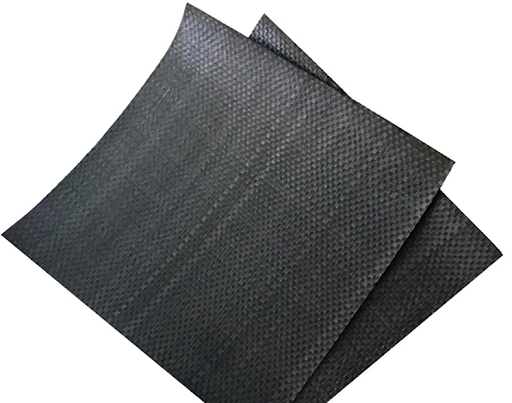

High-Strength Woven Geotextile – Superior Reinforcement for Soil Stabilization and Erosion Control

- Commodity name: High-Strength Woven Geotextile – Superior Reinforcement for Soil Stabilization and Erosion Control

Precise anti-filtration

Anti-puncture top

High-strength tensile

What Is High-Strength Woven Geotextile?

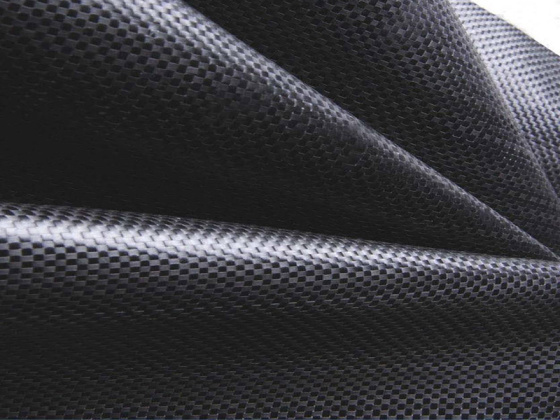

A high-strength woven geotextile is a durable fabric made by weaving high-tenacity polypropylene (PP) or polyester (PET) yarns into a stable, grid-like structure. It provides excellent tensile strength and low elongation, making it ideal for soil reinforcement, separation, and stabilization in civil and geotechnical engineering.

This type of geotextile is commonly used in road construction, embankments, retaining walls, and ground improvement for soft soil areas.

Key Technical Specifications:

-

Material: Polypropylene (PP) or Polyester (PET)

-

Tensile Strength: 50–200 kN/m

-

Elongation at Break: ≤ 20% (PP), ≤ 10% (PET)

-

Water Permeability: Good cross-plane drainage

-

Mass per Unit Area: 200–600 g/m²

-

UV & Chemical Resistance: Excellent

Applications of High-Strength Woven Geotextile

High-Strength Woven Geotextiles are used in a variety of soil stabilization, reinforcement, filtration, and erosion control applications. Some common uses include:

Soil Reinforcement: Provides reinforcement for road foundations, railway embankments, and slopes, preventing settlement and improving bearing capacity.

Erosion Control: Used to control erosion on riverbanks, coastal areas, and construction sites, preventing soil loss and stabilizing slopes.

Landfills: Applied in landfill liners to provide reinforcement and prevent deformation of the liner system while ensuring environmental protection.

Drainage Systems: Functions as a filter layer in drainage systems, allowing water to flow through while keeping soil particles in place.

Subgrade Reinforcement: Provides additional strength to subgrades in pavement and road construction, extending the lifespan of roadways by preventing pavement cracking and deformation.

Retaining Walls: Used in retaining walls to provide reinforcement and improve the stability of the structure.

The warp and weft interlaced structure gives it excellent tensile strength and tear resistance, maintaining structural stability under long-term loads. When laid between roadbeds or fillers, it can physically separate materials such as sand, gravel, and soil to prevent the reduction of bearing capacity caused by mixing.

The displacement of soil particles is constrained by friction, local stress is dispersed, and the coordinated force performance of the fill structure is improved. The mesh pore structure promotes the lateral drainage of water flow, reduces hydrostatic pressure, and avoids soil softening caused by water accumulation.

Looking forward to working with you

Sixteen foreign trade key account managers with more than ten years of engineering experience will promptly respond to any of your engineering questions. What are you waiting for? Let's get started.

Get A Quote

Note: Within a few minutes of filling out the form, you will receive the most timely and effective response.