Geocell – A Reliable Solution for Soil Stabilization and Erosion Control

- Commodity name: Geocell – A Reliable Solution for Soil Stabilization and Erosion Control

Anti-erosion soil consolidation

Three-dimensional reinforcement

Anti-aging

What Is Geocell?

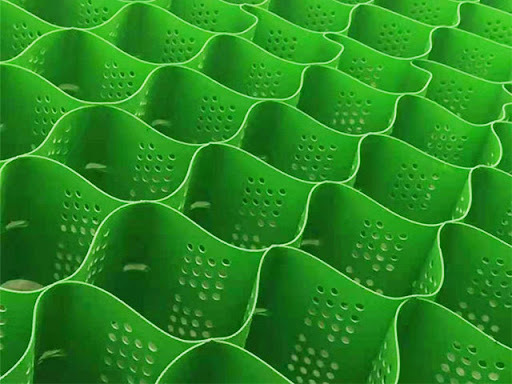

A geocell is a three-dimensional, honeycomb-like geosynthetic structure made from high-density polyethylene (HDPE) strips that are ultrasonically welded together. When expanded on-site and filled with soil, gravel, or concrete, geocells form a stable confinement system that distributes loads and prevents erosion, settlement, and soil migration.

Geocells are widely used in roadbeds, slopes, retaining walls, embankments, and erosion control applications.

Key Technical Specifications:

-

Material: High-Density Polyethylene (HDPE)

-

Cell Height: 50–200 mm (common: 100 mm, 150 mm)

-

Welding Distance: 330–1000 mm

-

Tensile Strength (per strip): ≥ 10–23 kN/m

-

UV and Chemical Resistance: Excellent

-

Cell Size: Customizable (commonly 356×356 mm expanded)

Applications of Geocell

The Geocell is ideal for a wide range of civil engineering and construction applications. Key uses include:

Soil Stabilization: Geocells provide reinforcement to soft or loose soils by preventing soil displacement. Common applications include roadbed reinforcement, railway embankments, and airport runways.

Slope Protection: Used to stabilize sloping terrains and prevent soil erosion. It is commonly applied in hilly areas, riverbanks, coastal areas, and highway embankments.

Retaining Walls: Geocells are ideal for constructing reinforced retaining walls, particularly for areas with unstable soil or high water tables.

Load Distribution: Geocells can improve the load-bearing capacity of soil in paved roads, parking lots, military airfields, and construction sites.

Erosion Control: When applied to areas prone to erosion, the honeycomb structure of geocells anchors soil particles, reducing water runoff and improving vegetation growth.

Vegetation Establishment: Geocells provide a stable environment for vegetation roots, making them ideal for green slopes, land reclamation projects, and green roofs.

Drainage Improvement: Geocells can be used in landfill projects and drainage systems, where they help manage water flow and reduce the risk of flooding.

The three-dimensional honeycomb structure tightly interlocks the filling material, greatly improving the lateral restraint of the soil and forming a highly stable composite bearing layer. The retractable unit freely fits the undulating base surface, effectively absorbing the uneven settlement of the foundation and reducing the risk of cracking of the rigid structure.

The cell space promotes the penetration and entanglement of vegetation roots, realizes the synergy of engineering reinforcement and natural greening, and curbs the erosion of the topsoil. The modular design supports rapid deployment of anchoring, reduces the use of traditional hard slope protection materials, and significantly reduces construction energy consumption and disturbance.

Product Introduction

Geocell is a three-dimensional network structure material made of polyethylene plastic sheets welded by high-strength ultrasonic waves. It uses local materials, sand, crushed stones, and soil as filling materials to form a composite material with a universal structure, achieving high bearing capacity. It can form a stable roadbed, and also plant grass on it, greening and stabilizing the slope.

|

Product Name |

Geocell |

|

Product Material |

HDPE |

|

Product Height |

50/75/100/150/200mm |

|

Welding Distance |

330/356/400/445/450/500/545/600/660/712/800/900/1000 |

|

Product Color |

Black, Green, Customized |

Product Specifications

|

Serial Number |

Test items |

Unit |

Geocell made of PP material |

Geocell made of PE material |

|

|

1 |

appearance |

|

The cells should be flat, without bubbles or grooves |

||

|

2 |

Tensile yield strength of cell sheets |

MPa |

≥23.0 |

≥20.0 |

|

|

3 |

Tensile strength of welded joints |

N/cm |

≥100 |

≥100 |

|

|

4 |

Tensile strength at the connection between cell groups |

Format Sheet Edge |

N/cm |

≥200 |

≥200 |

|

5 |

Format slice middle |

N/cm |

≥120 |

≥120 |

|

Product Features

1, flexible, transport can be folded, the construction can be stretched into a network, filled with soil, gravel.

concrete and other loose materials, to form a strong lateral limit and large stifness of the structure.

2, light material, wear resistance, chemical stability, light oxygen aging resistance, acid and alkali resistance.

suitable for different soil and desert soil conditions.

3, high side limit and anti-slip, anti-deformation, effectively enhance the bearing capacity of the roadbed anddisperse the load.

4, change the geocell height, welding distance and other geometric dimensions to meet diferent engineeringneeds.

5,flexible, small transport volume, convenient connection, fast construction speed.

Packing Details

1. HDPE geocells are packaged on pallets and secured with cable ties and plastic wrap. or as your requested;

Warning:Keeping away from fire and high temperatures.

Production workshop

Quality Inspection

Looking forward to working with you

Sixteen foreign trade key account managers with more than ten years of engineering experience will promptly respond to any of your engineering questions. What are you waiting for? Let's get started.

Get A Quote

Note: Within a few minutes of filling out the form, you will receive the most timely and effective response.