What are the Common Applications of HDPE Geomembrane? Practical Uses Across Industries

Time:

Jul 07,2025

What are the Common Applications of HDPE Geomembrane? Practical Uses Across Industries

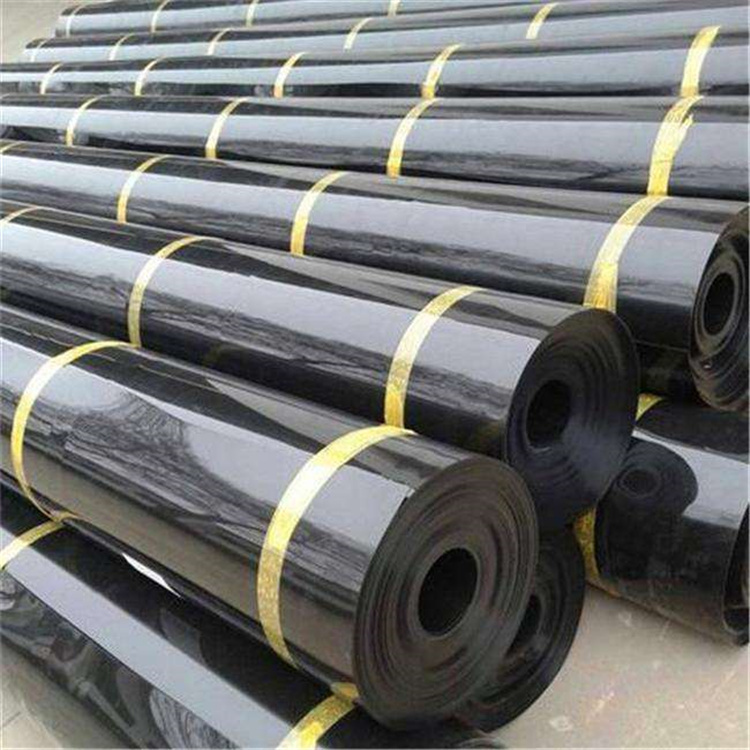

HDPE geomembrane isn’t just a sheet of plastic—it’s a powerful tool used globally for environmental protection, fluid containment, and infrastructure reliability. But where exactly is it used, and why is it the preferred material across so many sectors?

This article explores the most common, real-world applications of HDPE geomembrane and how it contributes to safety, sustainability, and cost efficiency.

1. Landfills: Environmental Protection from the Ground Up

In both municipal solid waste and hazardous waste landfills, HDPE geomembrane acts as a primary barrier between harmful leachate and the surrounding environment.

Bottom liner: Prevents leachate from seeping into soil and groundwater.

Cap or cover system: Prevents rainwater infiltration and controls gas emission.

✔ HDPE is chosen for its chemical resistance, UV stability, and long-term durability in harsh conditions.

2. Fish and Shrimp Ponds: Clean Water, Healthy Stock

Aquaculture relies heavily on water retention and hygiene. HDPE liners create a non-toxic, inert barrier that:

Prevents water seepage into the ground.

Reduces pathogen buildup.

Allows for easier cleaning and harvesting.

✔ Ideal for farms raising tilapia, catfish, shrimp, and other aquatic species.

3. Mining: Handling Extreme Chemical Exposure

In mining operations, HDPE geomembranes are used in:

Heap leach pads: Contain chemical solutions used to extract metals like gold or copper.

Tailing ponds: Store byproducts from ore processing.

Process water ponds: Prevent contaminated water from escaping.

✔ HDPE’s chemical and puncture resistance make it a top performer in aggressive mining environments.

4. Water Reservoirs and Tanks: Storing the Essential Resource

For irrigation, municipal supply, or industrial use, HDPE liners ensure water is stored safely without loss through seepage or contamination.

Reservoirs: Large-scale water containment in agriculture and drought-prone areas.

Potable water tanks: Lined with certified food-grade HDPE membranes.

✔ Long lifespan and low permeability reduce water loss and maintenance costs.

5. Wastewater Treatment Plants: Keeping Pollutants Confined

In sewage treatment or industrial effluent plants, HDPE liners are used to line:

Clarifiers

Sludge lagoons

Biological treatment ponds

✔ Prevents pollutants from entering surrounding soils and ecosystems.

6. Irrigation Canals: Efficient Water Delivery

HDPE-lined canals reduce seepage loss and prevent erosion, especially in sandy or permeable soils.

Easy to install in rural or large-scale agricultural settings.

Compatible with slope-protection systems.

✔ Significantly improves irrigation efficiency and conserves water.

7. Tunnels and Underground Structures: Waterproofing Below Ground

Tunnels, basements, and underground tanks often use HDPE liners for structural waterproofing, protecting against:

Groundwater infiltration

Moisture damage

Corrosion of embedded infrastructure

✔ When combined with geotextiles or drainage composites, HDPE offers superior underground protection.

Final Thoughts: Why HDPE is the Liner of Choice

HDPE geomembrane isn’t a one-size-fits-all solution—but it’s incredibly versatile and cost-effective across many industries. Its ability to withstand UV, chemicals, and mechanical stress makes it an essential material for projects that require high performance and long-term environmental security.

If you're working on a containment project, chances are HDPE geomembrane could be your smartest investment.