A Comprehensive Guide to Selecting the Right Bidirectional Plastic Geogrid for Your Construction Needs

Time:

Jun 02,2025

A Comprehensive Guide to Selecting the Right Bidirectional Plastic Geogrid Table of Contents Introduction to Bidirectional Plastic Geogrids What is a Bidirectional Geogrid? Benefits of Using Bidirectional Plastic Geogrids Key Features to Consider When Selecting a Geogrid Material Specifications for Bidirectional Geogrids Installation Techniques for Optimal Performance Applications o

A Comprehensive Guide to Selecting the Right Bidirectional Plastic Geogrid

Table of Contents

- Introduction to Bidirectional Plastic Geogrids

- What is a Bidirectional Geogrid?

- Benefits of Using Bidirectional Plastic Geogrids

- Key Features to Consider When Selecting a Geogrid

- Material Specifications for Bidirectional Geogrids

- Installation Techniques for Optimal Performance

- Applications of Bidirectional Plastic Geogrids in Construction

- Maintenance and Durability of Geogrids

- Frequently Asked Questions

- Conclusion

Introduction to Bidirectional Plastic Geogrids

The construction industry is constantly evolving, and the demand for reliable, effective, and sustainable materials is at an all-time high. Among the many tools used to enhance soil stability and improve load-bearing capacities, bidirectional plastic geogrids stand out as a preferred choice for many construction projects. This guide aims to provide invaluable insights into selecting the right bidirectional plastic geogrid, ensuring optimal results for your construction needs.

What is a Bidirectional Geogrid?

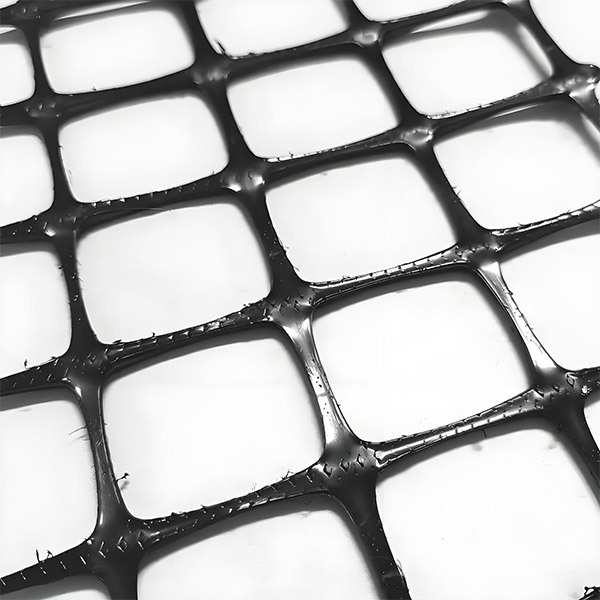

A bidirectional geogrid is a synthetic material made from high-density polyethylene (HDPE), polypropylene, or other polymers, designed with a network of interconnected ribs or apertures. These geogrids are engineered to provide reinforcement in both longitudinal and transverse directions, allowing for enhanced load distribution and soil stabilization in various applications.

Unlike unidirectional geogrids, which only provide reinforcement in one direction, bidirectional geogrids offer superior performance in scenarios where loads are applied from multiple directions. This makes them an ideal choice for various applications, including road construction, embankment stabilization, and retaining wall support.

Benefits of Using Bidirectional Plastic Geogrids

Choosing the right geogrid can significantly impact the success of your project. Here are some critical benefits of using bidirectional plastic geogrids:

1. Enhanced Load Distribution

Bidirectional geogrids effectively distribute loads across a wider area, reducing soil deformation and preventing failure. This is particularly beneficial in heavy traffic areas or locations with unstable soil conditions.

2. Improved Stability

By reinforcing the soil matrix, these geogrids help maintain the integrity of the ground, preventing issues such as settlement and erosion. As a result, structures built on reinforced soil are more stable and durable.

3. Cost-Effectiveness

While the initial investment may be higher than traditional methods, using bidirectional geogrids can lead to significant savings in the long run. They reduce the need for excess fill material, minimize maintenance costs, and shorten project timelines.

4. Environmentally Friendly

Many bidirectional geogrids are made from recycled materials, making them a sustainable option for construction projects. Their long lifespan also contributes to reducing waste.

5. Versatility in Applications

Bidirectional plastic geogrids are suitable for various applications, including roadways, parking lots, slopes, and retaining walls. Their versatility makes them a preferred choice for engineers and contractors alike.

Key Features to Consider When Selecting a Geogrid

When choosing a bidirectional plastic geogrid, several key features should be considered to ensure optimal performance:

1. Tensile Strength

The tensile strength of a geogrid refers to its ability to withstand pulling forces without breaking. It is essential to select a geogrid with adequate tensile strength to support the expected loads in your specific application.

2. Opening Size

The size of the openings in the geogrid plays a crucial role in how well it interacts with the soil. Larger openings allow for better drainage and soil interlocking, while smaller openings may be better suited for finer soils.

3. Polymer Type

Different polymers provide varying levels of durability, flexibility, and resistance to environmental factors. Understanding the specific conditions of your project site will help determine the best polymer type to use.

4. Installation Method

Each geogrid type may require a different installation approach. Familiarizing yourself with the recommended installation techniques is crucial for ensuring optimal performance.

5. Compliance and Certification

Ensure that the selected geogrid complies with relevant industry standards and certifications. This guarantees that the product meets quality and performance expectations.

Material Specifications for Bidirectional Geogrids

Understanding the material specifications of bidirectional plastic geogrids is essential for making informed decisions. Key considerations include:

1. High-Density Polyethylene (HDPE)

HDPE is a common material used in geogrid manufacturing due to its excellent tensile strength and resistance to UV light and chemicals. It is ideal for outdoor applications where exposure to harsh conditions is expected.

2. Polypropylene

Polypropylene geogrids are lightweight and provide good flexibility and durability. They are often used in applications where weight is a concern, such as in road construction.

3. Recycled Materials

Some manufacturers produce geogrids from recycled materials, making them an eco-friendly option. While these may offer similar performance characteristics, it is crucial to ensure that they meet the necessary quality standards.

Installation Techniques for Optimal Performance

Proper installation of bidirectional plastic geogrids is critical to maximize their effectiveness. Here are key steps to follow during the installation process:

1. Site Preparation

Ensure that the site is properly prepared by removing any debris, vegetation, or loose soil that could interfere with the geogrid's performance. The subgrade must be stable and free of soft spots.

2. Layering the Geogrid

Carefully lay the geogrid over the prepared surface, ensuring that it is taut and free from wrinkles. Overlapping sections may be necessary in some cases, so pay close attention to the manufacturer's guidelines.

3. Backfilling

Once the geogrid is in place, backfill with appropriate materials. The backfill should be compacted to ensure proper soil interlocking and to achieve the desired load distribution.

4. Monitoring and Maintenance

Post-installation, it’s essential to monitor the performance of the geogrid and perform any necessary maintenance. Address any signs of settlement or erosion promptly to prolong the lifespan of the installation.

Applications of Bidirectional Plastic Geogrids in Construction

Bidirectional plastic geogrids find utility in various construction applications, including:

1. Road Construction

In road construction, geogrids are used to reinforce subgrade soils, improve load-bearing capacity, and extend the lifespan of pavement structures.

2. Retaining Walls

Geogrids can be used to create reinforced soil structures for retaining walls, providing additional stability and preventing failure under lateral earth pressures.

3. Slope Stabilization

Bidirectional geogrids are effective in stabilizing slopes by preventing soil erosion and promoting vegetation growth.

4. Parking Lots

In parking lots, geogrids help distribute loads from vehicles, reducing the risk of pavement cracking and deformation.

Maintenance and Durability of Geogrids

To ensure the longevity and effectiveness of bidirectional plastic geogrids, regular maintenance is advisable. Here are some best practices:

1. Routine Inspections

Conduct routine inspections to identify any signs of damage or displacement. Early detection allows for prompt repairs, maintaining optimal performance.

2. Erosion Control

Implement measures to control erosion in areas where geogrids are installed. This can include vegetation planting or using erosion control blankets.

3. Addressing Settlements

If settlements occur, address them immediately by adding additional fill or re-compacting existing materials to prevent further issues.

Frequently Asked Questions

1. What is the expected lifespan of bidirectional plastic geogrids?

Bidirectional plastic geogrids are designed to last for several decades, often exceeding 20 years, depending on environmental conditions and proper installation.

2. Can bidirectional geogrids be used in wet conditions?

Yes, bidirectional geogrids are effective in wet conditions. Their design allows for drainage, reducing the risk of water pooling and soil saturation.

3. How do I determine the right tensile strength for my application?

The required tensile strength depends on the expected loads and the type of soil. Consulting with an engineer can help you determine the appropriate specifications for your project.

4. Are bidirectional geogrids easy to install?

While installation can be straightforward, it requires careful attention to detail and adherence to manufacturer guidelines for optimal performance.

5. Can I use bidirectional geogrids for residential projects?

Absolutely! Bidirectional geogrids are versatile and can be effectively utilized in both commercial and residential projects to enhance soil stability.

Conclusion

Selecting the right bidirectional plastic geogrid is crucial for the success of your construction projects. With their ability to enhance load distribution, improve stability, and reduce costs, these geogrids provide an invaluable resource for engineers and contractors alike. By considering factors such as material specifications, installation techniques, and application needs, you can make informed decisions that lead to successful outcomes. With this comprehensive guide at your disposal, you are now better equipped to select the best bidirectional plastic geogrid for your specific construction needs, ensuring long-lasting performance and reliability.