The Science Behind Dacron Geogrid: Strengthening Foundations

Time:

Jun 12,2025

The Science Behind Dacron Geogrid: Strengthening Foundations Table of Contents 1. Introduction to Dacron Geogrids 2. Understanding Geogrid Technology 3. The Chemical Composition of Dacron 4. Key Benefits of Using Dacron Geogrids 4.1 Enhanced Load Distribution 4.2 Increased Soil Stability 4.3 Cost-Effectiveness in Construction 5. Applications of Dacron Geogrids in Construction 5.1 Road and Highway

The Science Behind Dacron Geogrid: Strengthening Foundations

Table of Contents

1. Introduction to Dacron Geogrids

2. Understanding Geogrid Technology

3. The Chemical Composition of Dacron

4. Key Benefits of Using Dacron Geogrids

4.1 Enhanced Load Distribution

4.2 Increased Soil Stability

4.3 Cost-Effectiveness in Construction

5. Applications of Dacron Geogrids in Construction

5.1 Road and Highway Construction

5.2 Retaining Walls and Slopes

5.3 Embankment Stabilization

6. Installation Techniques for Dacron Geogrids

7. Case Studies: Success Stories with Dacron Geogrids

8. Frequently Asked Questions about Dacron Geogrids

9. Conclusion

1. Introduction to Dacron Geogrids

Dacron geogrids have emerged as a game-changer in the construction industry, particularly in enhancing the strength and stability of foundations. With a focus on performance, these materials are engineered to provide superior support in various applications, making them indispensable in modern construction practices. This article delves into the science behind Dacron geogrids, exploring their composition, advantages, applications, and installation techniques.

2. Understanding Geogrid Technology

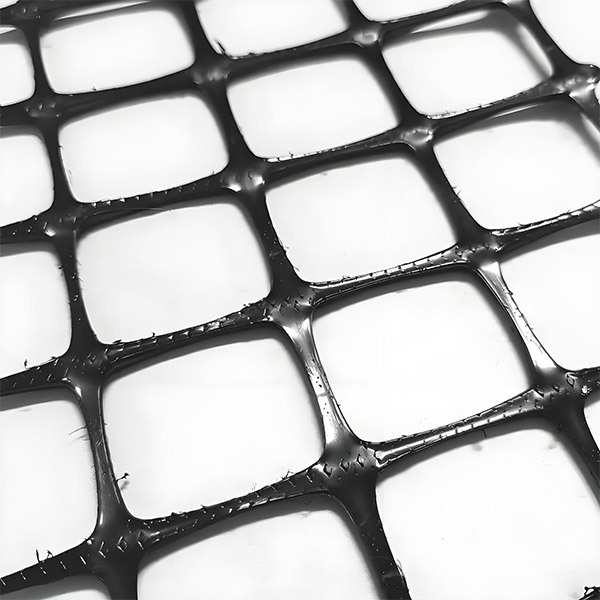

Geogrids are geosynthetic materials used to reinforce soils and other materials. They consist of a network of intersecting ribs that create a grid-like structure. This design enhances the load-bearing capacity of the soil, allowing for more effective distribution of stresses. The innovative technology behind geogrids, particularly those made from Dacron, plays a significant role in achieving long-lasting and durable foundations.

3. The Chemical Composition of Dacron

Dacron is a brand name for a type of polyester fabric made from polyethylene terephthalate (PET). Known for its strength, durability, and resistance to environmental factors, Dacron's chemical composition includes:

- **Polyethylene Terephthalate (PET)**: This thermoplastic polymer is known for its high tensile strength and low moisture absorption.

- **Stabilizers and Additives**: These components enhance Dacron's resistance to UV degradation and various chemicals, ensuring longevity in diverse environmental conditions.

The unique characteristics of Dacron make it an ideal choice for geogrid applications, offering enhanced performance in soil stabilization.

4. Key Benefits of Using Dacron Geogrids

4.1 Enhanced Load Distribution

One of the most significant advantages of Dacron geogrids is their ability to evenly distribute loads across a larger area. This feature prevents localized failures in the soil, thereby extending the lifespan of pavements and structures built on top of them. The grid structure effectively bears the weight of vehicles and heavy machinery, reducing the risk of sagging or settling.

4.2 Increased Soil Stability

Dacron geogrids enhance soil stability by interlocking with surrounding soil particles. This interlocking mechanism improves the overall shear strength of the soil, preventing erosion and slippage. In areas prone to landslides or where the ground is unstable, Dacron geogrids provide critical support, ensuring that structures remain secure and safe.

4.3 Cost-Effectiveness in Construction

Using Dacron geogrids can lead to significant cost savings in construction. By reducing the amount of additional material needed for stabilizing soils, these geogrids minimize labor and material costs. Additionally, their durability and strength can lead to fewer repairs and maintenance over time, providing an economically viable solution for construction projects.

5. Applications of Dacron Geogrids in Construction

Dacron geogrids find diverse applications in construction, owing to their superior performance characteristics. Some of the key areas include:

5.1 Road and Highway Construction

In road construction, Dacron geogrids are used to reinforce sub-base layers, improving load distribution and extending the life of the roadway. They help prevent pavement cracking and deformation, ensuring safer and more durable roads.

5.2 Retaining Walls and Slopes

Dacron geogrids are crucial in constructing retaining walls and stabilizing slopes. Their high tensile strength allows them to support vertical loads and resist lateral pressures, providing stability to earth-retaining structures.

5.3 Embankment Stabilization

In embankment applications, Dacron geogrids enhance the structural integrity of slopes. They prevent soil erosion and sliding, allowing for the safe construction of embankments, which is particularly important in areas with heavy rainfall or seismic activity.

6. Installation Techniques for Dacron Geogrids

Implementing Dacron geogrids requires careful planning and execution to achieve optimal results. The installation process typically involves the following steps:

1. **Site Preparation**: The area where the geogrid will be installed must be cleared and leveled. Any organic material or loose soil should be removed to ensure proper adhesion and stability.

2. **Geogrid Placement**: Dacron geogrids should be laid flat on the prepared surface. Proper alignment and tensioning are critical to ensuring their effectiveness.

3. **Backfill Application**: Once positioned, backfill material is applied over the geogrid. This material should be compacted to enhance the interlocking effect between the geogrid and soil.

4. **Quality Control**: Regular inspections during installation will ensure that the geogrid remains positioned correctly and retains its intended function.

Proper installation techniques can significantly influence the performance of Dacron geogrids, enhancing their effectiveness in reinforcing foundations.

7. Case Studies: Success Stories with Dacron Geogrids

Numerous case studies illustrate the successful application of Dacron geogrids in various construction projects. In one notable instance, a highway expansion project utilized Dacron geogrids to stabilize the sub-base, resulting in a 30% reduction in material costs and improved load-bearing capacity. Another case involved the construction of a retaining wall that effectively prevented soil slippage, ensuring the safety of nearby structures. These examples underscore the versatility and effectiveness of Dacron geogrids in real-world applications.

8. Frequently Asked Questions about Dacron Geogrids

What is the lifespan of Dacron geogrids?

Dacron geogrids can last many years, often exceeding 25 years, depending on environmental conditions and installation practices.

Are Dacron geogrids environmentally friendly?

Yes, Dacron geogrids are designed to have minimal environmental impact. Their durability reduces the need for frequent replacements, contributing to less waste over time.

Can Dacron geogrids be used in high-traffic areas?

Absolutely. They are specifically engineered to withstand high loads, making them suitable for highways and commercial roadways.

How do Dacron geogrids compare to other geogrid materials?

Dacron geogrids offer superior tensile strength and resistance to environmental degradation compared to other materials, such as polypropylene.

Are there specific design considerations for using Dacron geogrids?

Yes, factors such as soil type, load requirements, and environmental conditions must be considered to ensure effective use of Dacron geogrids in construction.

9. Conclusion

Dacron geogrids represent a significant advancement in construction materials, providing essential support for a variety of applications. Their unique chemical composition, combined with innovative design, results in enhanced soil stability, efficient load distribution, and cost-effectiveness. As the construction industry continues to evolve, incorporating Dacron geogrids into foundational work will undoubtedly lead to safer, more durable structures. Understanding the science behind these materials empowers engineers and construction professionals to make informed decisions, ultimately strengthening the foundations of our built environment.