What Makes HDPE Geomembrane Ideal for Landfill and Mining Projects?

Time:

Jul 09,2025

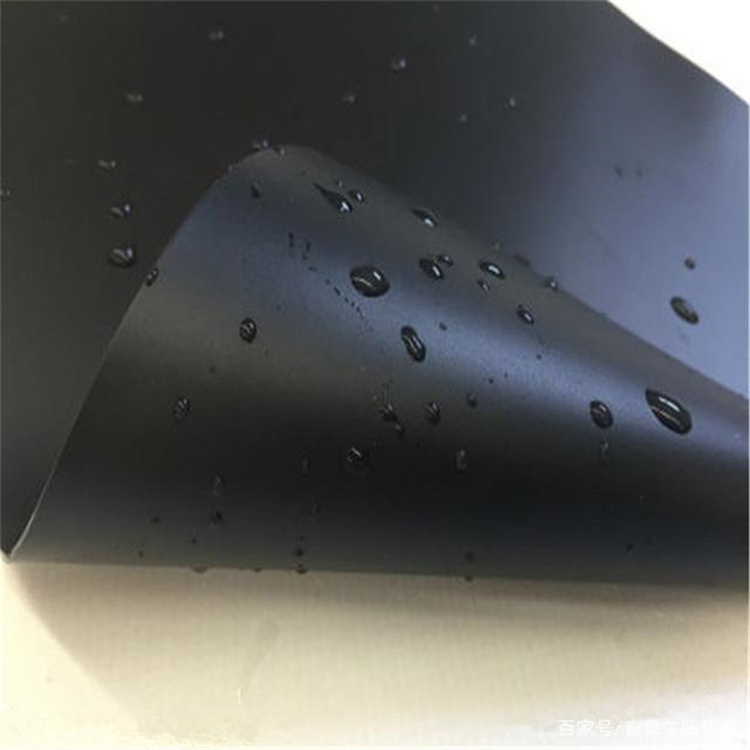

HDPE geomembrane has become the standard lining material for modern landfill containment and mining operations worldwide. Its unique combination of chemical resistance, mechanical strength, and cost-effectiveness makes it the preferred solution in harsh and highly regulated environments.

This article explores why HDPE geomembrane is the first choice for engineers and environmental managers in waste management and resource extraction industries.

1. Superior Chemical Resistance in Harsh Conditions

Landfills and mines generate aggressive leachates that often contain acids, salts, hydrocarbons, and heavy metals. HDPE geomembrane offers excellent resistance to a wide range of chemicals, including:

Sulfuric and hydrochloric acid

Sodium chloride and sulfates

Organic solvents and fuels

Cyanide and arsenic compounds used in gold and copper mining

This resistance ensures that contaminants do not leach into the surrounding soil and groundwater, helping site owners meet environmental regulations and avoid heavy penalties.

2. Long-Term Durability Under Load and Stress

Landfill liners must endure not only chemical attack but also constant mechanical stress from waste loads and settlement. Similarly, mining tailings exert high hydrostatic pressure over long periods. HDPE geomembrane has:

High tensile strength

Excellent puncture and tear resistance

Low permeability

Long service life (typically 50+ years under protected conditions)

These properties make HDPE a reliable liner in projects where long-term containment is non-negotiable.

3. UV and Weather Resistance in Harsh Climates

In mining operations, especially in remote or high-altitude regions, geomembranes may be left exposed for extended periods. HDPE geomembrane includes carbon black and UV stabilizers, allowing it to withstand direct sunlight, temperature variations, and freeze-thaw cycles. This UV resistance helps maintain liner integrity even in exposed slope applications such as heap leach pads.

4. Meets International Liner Standards

Most countries require engineered landfills and mining containment systems to meet international liner standards such as GRI-GM13. HDPE geomembranes manufactured to these specifications guarantee minimum mechanical properties, environmental safety, and consistent quality—something not all alternative liners can offer.

5. Compatible With Double-Liner Systems and Leak Detection

In hazardous waste landfills and mine tailings ponds, double-liner systems are often required. HDPE geomembrane is compatible with:

Geosynthetic clay liners (GCLs)

Drainage geonets

Leak detection systems

Geotextiles and sand protection layers

Its flexibility and weldability make it ideal for complex multi-layered containment systems.

6. Easy to Weld and Test for Leak Prevention

HDPE geomembrane can be easily seamed using hot wedge or extrusion welding. Welded joints can be tested using air pressure or vacuum methods to ensure a fully leak-proof barrier. This is especially critical in landfills, where even minor leaks can lead to environmental contamination and legal liabilities.

7. Cost-Effective Over the Life of the Project

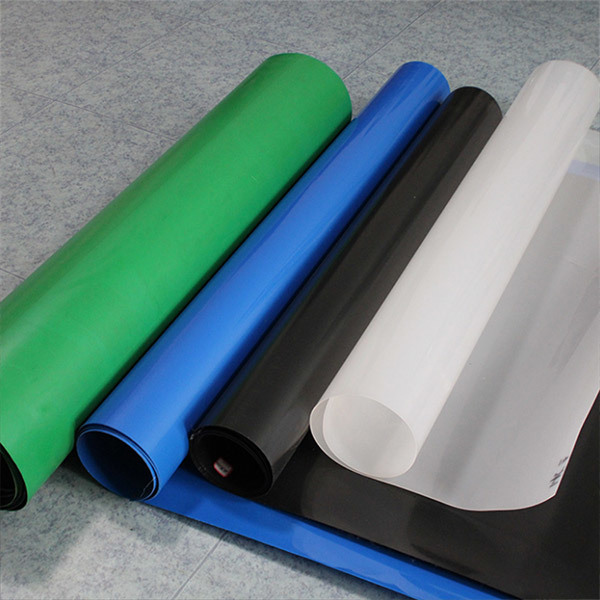

Although HDPE geomembrane may have a higher upfront cost than some alternatives (such as PVC or LDPE), its lower failure rate, long lifespan, and minimal maintenance requirements make it a more cost-effective solution over time.

In the mining sector, proper containment of cyanide or tailings can prevent catastrophic spills that may cost millions in fines and remediation. HDPE liners provide a cost-efficient insurance policy against such risks.

Typical Applications in Landfill and Mining Projects

Municipal and industrial solid waste landfills

Hazardous waste containment

Leachate ponds and collection trenches

Tailings dams and slurry impoundments

Heap leach pads in gold and copper mining

Sediment basins and stormwater control

Conclusion: Why HDPE Geomembrane Remains the Industry Standard

When it comes to critical environmental protection in landfill and mining operations, HDPE geomembrane consistently outperforms alternative solutions. Its resistance to chemicals, UV rays, and mechanical damage—combined with its long service life and ease of installation—makes it the most trusted containment liner in the world.

Partner with a Reliable HDPE Geomembrane Manufacturer

We manufacture and export high-quality HDPE geomembranes that comply with international standards and are trusted in landfill and mining projects across five continents. If you’re designing a waste containment system, our technical team can help you select the right liner thickness, roll size, and welding approach.

Contact us today for a free quote, samples, or technical consultation. Let’s build something that lasts.