Brief Introduction to Geocells Geocells are three-dimensional, honeycomb-like structures made from durable polymer materials such as polyethylene or polypropylene. They are used in civil engineering for soil stabilization, slope protection, and erosion control. When expanded, geocells form a flexible grid that can be filled with soil, gravel, or concrete, providing enhanced load-bearing capacity and stability. Their key features include high strength, permeability, corrosion resistance, and ease of installation. Geocells are widely applied in road construction, embankment reinforcement, and environmental protection projects due to their cost-effectiveness and ability to improve project durability. Brief Introduction to Geocell Specifications Geocells are available in various specifications to suit different engineering needs. Common parameters include:Material: Typically made from high-density polyethylene (HDPE) or polypropylene (PP).Cell Size: Ranges from 100 mm to 300 mm in diameter, depending on the application.Cell Depth: Usually between 50 mm and 200 mm, adjustable based on project requirements.Sheet Size: Standard sheets are often 4-8 meters in length and 2-4 meters in width.Thickness: Wall thickness generally ranges from 1.0 mm to 1.5 mm, ensuring durability and flexibility.Color: Commonly black or green, depending on the material and application.These specifications can be customized to meet specific project demands, ensuring optimal performance in soil stabilization, slope protection, and other civil engineering applications.

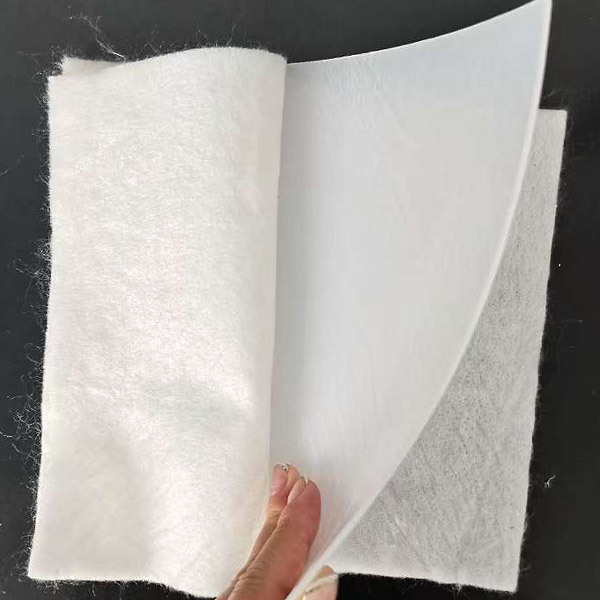

Waterproof Composite Geomembrane

The composite geomembrane is divided into one cloth and one membrane and two cloth and one membrane, and the composite geomembrane can meet the needs of civil engineering such as anti-seepage

Compared with the traditional cloth and membrane separation, the use of composite geomembrane improves the use effect, saves the project time, reduces the project cost, and the comprehensive benefits are obvious.

Polyethylene Composite Geomembrane

Environmental protection and sanitation projects (such as domestic waste landfills, sewage treatment plants, toxic and harmful substances treatment sites).

Polyethylene composite geomembrane is a highly effective material with a wide range of applications.

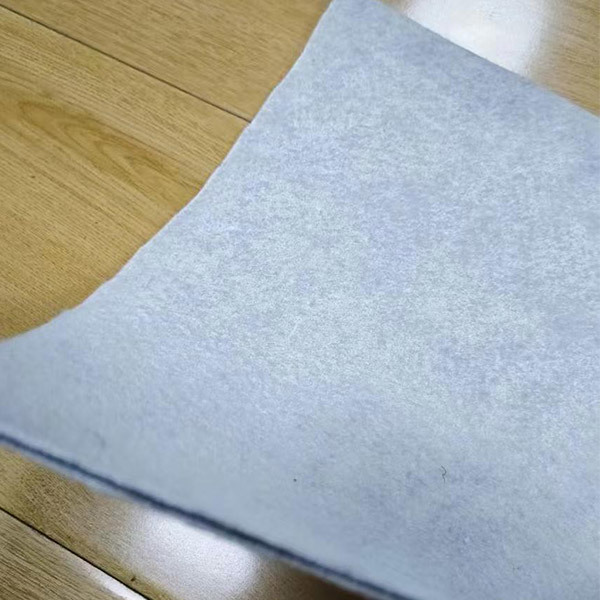

On-woven Composite Geomembrane

The width can reach six meters, compared with similar products with narrow width, it reduces the joints, reduces the project cost, shortens the construction period, and also reduces the hidden dangers caused by improper joint treatment.

Three-dimensional geotextile mat

Three-dimensional vegetation network slope protection refers to the use of active plants and combined with geosynthetics and other engineering materials to build a protection system with its own growth ability on the slope surface

Three-dimensional vegetation nets

The anti-erosion effect of vegetation is that the plant growth layer (including perianth, leaf sheath, leaves, and stems) prevents the slope surface soil from being directly eroded by rainwater through its own dense covering layer.

Staple fiber needle punched nonwoven geotextile

Polypropylene geotextile can be widely used in hydropower, highways, railways, ports, airports, sports venues, tunnels, coastal mudflats, reclamation, environmental protection and other fields to play an isolation