Choosing the Right Composite Geomembrane: A Comprehensive Guide to Geosynthetic Solutions

Time:

Sep 20,2025

Choosing the Right Composite Geomembrane: A Comprehensive Guide to Geosynthetic Solutions Table of Contents 1. Introduction to Composite Geomembranes 2. What Are Composite Geomembranes? 3. Types of Composite Geomembranes 3.1 HDPE Composite Geomembranes 3.2 LDPE Composite Geomembranes 3.3 PP Composite Geomembranes 4. Application

Choosing the Right Composite Geomembrane: A Comprehensive Guide to Geosynthetic Solutions

Table of Contents

- 1. Introduction to Composite Geomembranes

- 2. What Are Composite Geomembranes?

- 3. Types of Composite Geomembranes

- 4. Applications of Composite Geomembranes

- 5. Factors to Consider When Choosing a Composite Geomembrane

- 6. Installation Techniques for Composite Geomembranes

- 7. Maintenance and Inspection of Geomembranes

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Composite Geomembranes

Composite geomembranes play a crucial role in **environmental protection** and construction projects. These versatile materials serve as barriers against liquids and gases, ensuring safety and sustainability. In this guide, we will explore the intricacies of composite geomembranes, helping you make informed choices for your projects.

2. What Are Composite Geomembranes?

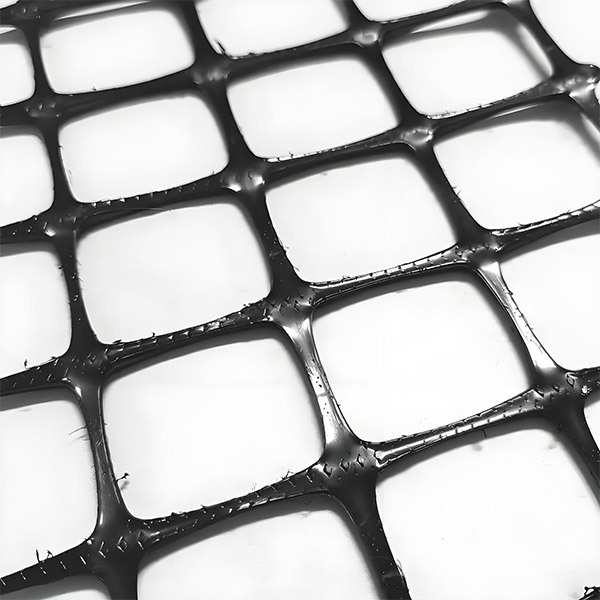

Composite geomembranes are engineered materials that comprise multiple layers. Typically consisting of a polymer layer bonded to a geotextile layer, these geomembranes provide enhanced functionality, durability, and versatility. The polymer layer offers resistance to chemical attacks and punctures, while the geotextile layer improves drainage and filtration capabilities.

3. Types of Composite Geomembranes

Understanding the different types of composite geomembranes is essential for selecting the right one for your project. Each type has unique properties and applications.

3.1 HDPE Composite Geomembranes

High-Density Polyethylene (HDPE) composite geomembranes are known for their exceptional chemical resistance and durability. They are widely used in landfills, ponds, and environmental containment applications. HDPE geomembranes can withstand harsh environmental conditions, making them ideal for various projects.

3.2 LDPE Composite Geomembranes

Low-Density Polyethylene (LDPE) composite geomembranes are more flexible than their HDPE counterparts. They are often used in applications requiring high flexibility and elongation properties. LDPE geomembranes are ideal for curved surfaces and complex geometries.

3.3 PP Composite Geomembranes

Polypropylene (PP) composite geomembranes offer excellent UV resistance and thermal stability. They are suitable for applications that involve exposure to sunlight and varying temperatures. PP geomembranes are often employed in agricultural and landscaping projects.

4. Applications of Composite Geomembranes

Composite geomembranes find applications across various sectors:

- **Landfills**: They provide effective containment of leachate and prevent soil and groundwater contamination.

- **Water Reservoirs and Ponds**: Composite geomembranes act as liners to prevent water loss and protect the environment.

- **Mining Operations**: Used for tailings storage and heap leach pads, they ensure responsible environmental management.

- **Agriculture**: They help in irrigation systems and landscape applications, optimizing water usage and protecting soil.

5. Factors to Consider When Choosing a Composite Geomembrane

Selecting a composite geomembrane involves careful consideration of various factors to ensure optimal performance and longevity.

5.1 Environmental Conditions

Evaluate the environmental conditions in which the geomembrane will be installed. Factors such as temperature fluctuations, UV exposure, and chemical exposure should influence your choice. For example, HDPE geomembranes excel in harsh chemicals, while PP geomembranes thrive in direct sunlight.

5.2 Project Requirements

Understand your project's specific requirements, including the intended use, volume of fluids to be contained, and duration of exposure. Each project has unique demands that can guide your selection.

5.3 Material Properties

Examine the material properties of the geomembrane, such as permeability, tensile strength, and puncture resistance. The right material will ensure the geomembrane can withstand the stresses it will encounter.

6. Installation Techniques for Composite Geomembranes

Proper installation is critical for the effectiveness of composite geomembranes. Here are some essential techniques to follow:

1. **Site Preparation**: Ensure the installation site is clean and free of sharp objects that may puncture the geomembrane.

2. **Cutting and Laying**: Use precise cutting techniques to fit the geomembrane to the required dimensions and lay it flat to avoid wrinkles.

3. **Seaming**: Employ appropriate seaming methods, such as thermal welding or adhesive bonding, to ensure a strong connection between geomembrane sections.

4. **Testing**: Perform hydraulic and integrity tests to verify the geomembrane's effectiveness after installation.

7. Maintenance and Inspection of Geomembranes

Ongoing maintenance and inspection are essential to prolong the lifespan of composite geomembranes:

- **Regular Inspections**: Schedule routine inspections to identify potential damage or wear in the geomembrane.

- **Repair Techniques**: Utilize appropriate repair techniques such as patching or reseaming to address any issues promptly.

- **Environmental Monitoring**: Monitor the surrounding environment to ensure no adverse conditions compromise the geomembrane's integrity.

8. Frequently Asked Questions

1. What are the main advantages of using composite geomembranes?

Composite geomembranes provide enhanced durability, chemical resistance, and flexibility compared to traditional liners. Their multi-layer design allows for better performance in various applications.

2. How long do composite geomembranes last?

The lifespan of composite geomembranes varies based on material properties and environmental conditions. Typically, they can last 20 to 30 years with proper installation and maintenance.

3. Can composite geomembranes be recycled?

Yes, composite geomembranes made from certain materials like HDPE can be recycled. However, it's essential to follow local regulations and guidelines for recycling.

4. How do I choose the right thickness for a geomembrane?

The thickness of the geomembrane should be determined based on the application requirements, including the type of fluids contained and the environmental stresses it will face.

5. Are composite geomembranes environmentally friendly?

Composite geomembranes are designed to protect the environment from contamination. When installed and maintained correctly, they can effectively minimize ecological impacts.

9. Conclusion

Choosing the right composite geomembrane is a critical decision that can significantly impact the success of your project. By understanding the various types, applications, and factors to consider, you can make an informed choice that meets your specific needs. With proper installation, maintenance, and regular inspection, composite geomembranes can provide a long-lasting solution for environmental protection and construction projects.