Waterproof Geomembrane

- Commodity name: Waterproof Geomembrane

Keyword:

Waterproof Geomembrane

- PRODUCT DESCRIPTION

Geomembrane is a geosynthetic material specifically designed to prevent water, liquid or gas permeation. It is a film-like material made of polymer materials such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE).

specification

The thickness is 0.15-3.0mm, and the width is 4-8m (commonly used 6m, 8m, easy to transport),

Roll length 50-200m (length according to engineering design and customer requirements).

peculiarity

1. Good flexibility and high impermeability coefficient;

2. Good heat and cold resistance, wide range of ambient temperature (-70°C-110°C)

3. Good chemical stability, strong acid and alkali resistance, strong anti-corrosion performance;

4. It has strong weather resistance and excellent anti-aging performance

5. The tensile strength and elongation at break index are high, the strain force is strong, and it can be used under various harsh geological and climatic conditions, especially suitable for the project of uneven geological settlement.

The role of geomembranes

1. Impermeability

Geomembrane has good anti-seepage performance and can effectively prevent the leakage of liquid and gas. In water conservancy projects, it can be used for anti-seepage treatment of reservoirs, dams, reservoirs, etc., to reduce the loss of water resources. In addition, in the fields of chemical industry and mining, geomembranes can also be used to prevent the leakage of chemicals and slag and protect the environment and human health.

2. Enhancements

Geomembranes have good tensile and tear strength, which can enhance the bearing capacity and stability of the soil. In civil engineering, it can be used in embankments, earth dams and other projects to improve the overall stability of the project. In addition, in geotechnical engineering, tunnel engineering and other fields, geomembranes can also be used to strengthen the soil and enhance the stability of the rock mass.

The use of geomembranes

1. Hydraulic engineering

In water conservancy projects, geomembranes are widely used in anti-seepage treatment of reservoirs, dams, reservoirs, etc. It can effectively reduce the loss of water resources and improve the efficiency of water conservancy projects. Geomembrane can also be used for slope protection and riverbed laying to protect the structural safety of the project.

2. Civil Engineering

In civil engineering, geomembranes are widely used in embankments, earth dams and other projects. It can improve the overall stability of the project and prolong the service life of the project. At the same time, geomembranes can also be used for reinforcement and waterproofing of tunnel projects.

3. Environmental governance

In the field of environmental treatment, geomembranes are widely used in environmental protection engineering and soil remediation. It can effectively prevent the leakage of chemical substances and slag, protect the environment and human health. At the same time, geomembranes can also be used for the remediation and treatment of soil pollution, improving soil quality and ecological environment.

4. Other areas

In addition to the above application fields, geomembranes are also widely used in construction, mining, transportation and other fields. It can effectively solve the problems of seepage, reinforcement and waterproofing in various engineering construction, and improve the safety and stability of the project.

Main applications:

1. HDPE geomembrane is suitable for environmental protection and sanitation: such as landfills, sewage treatment plants, power plant regulating tanks, industrial, hospital solid waste, etc.;

2. LDPE impermeable membrane is suitable for water conservancy projects: such as anti-seepage, plugging and reinforcing of rivers, lakes and reservoirs, seepage prevention of canals, vertical core walls, slope protection, etc.;

3. HDPE impermeable membrane in municipal engineering: subway, building underground engineering, planting roof, roof garden, sewage pipe seepage;

4. Polyethylene impermeable membrane is suitable for gardens: artificial lakes, rivers, reservoirs, pond bottoms of golf courses, slope protection, green lawns waterproof and moisture-proof, etc.;

5. High-density polyethylene geomembrane is suitable for petrochemical: chemical plants, oil refineries, oil storage tanks, chemical reaction tanks, sedimentation tank lining, secondary lining, etc.;

6. Polyethylene geomembrane is suitable for mining: washing tank, heap leaching tank, ash dump, dissolution tank, sedimentation tank, stockpile, tailings bottom lining anti-seepage, etc.;

7. Low-density polyethylene film is suitable for traffic facilities: foundation reinforcement of highways and seepage prevention of culverts;

8. LDPE impermeable membrane is suitable for agriculture: anti-seepage of reservoirs, drinking water pools, reservoirs and irrigation systems;

9. HDPE film is suitable for aquaculture industry: intensive, factory breeding ponds, fish ponds, shrimp pond lining, sea cucumber circle slope protection, etc.;

10. High-density polyethylene impermeable membrane is suitable for salt industry: salt field crystallization pool, brine pond cover, salt film, salt pond plastic film [2].

Construction method

The geomembrane should not be dragged or dragged hard during transportation to avoid being punctured by sharp objects.

1. It should be extended from the bottom to the high, not too tight, and a margin of 1.50% should be left for local sinking and stretching. Considering the actual situation of this project, the slope adopts the laying sequence from top to bottom;

2. The longitudinal joints of two adjacent beams should not be on a horizontal line, and should be staggered more than 1m from each other;

3. The longitudinal joint should be more than 1.50m away from the dam foot and bend foot, and should be located on the plane;

4. First the slope and then the bottom of the field;

5. When the slope is laid, the direction of the film should be basically parallel to the maximum slope line.

Product specifications and performance parameters

| Item/Specification | LDPE geomembrane | HDPE geomembrane | EVA geomembrane | |

| Ordinary type GH-1 | Environmentally-friendly GH-2 | |||

| Tensile strength | 14 | 17 | 25 | 16 |

| Elongation at break | 400 | 450 | 550 | 550 |

| Right-angle tear strength | 50 | 80 | 110 | 60 |

| Carbon black content | 2 | 2 | ||

| Resistant to environmental stress cracking | 1500 | |||

| Oxidation induction time at 200°C | 20 | |||

| -70°C low temperature impact embrittlement performance | Pass | |||

| Dimensional stability | ±3 | ±3 | ||

United States GSE HDPE geomembrane product specifications and performance indicators

| Test metrics | Test Method | Test frequency | Minimum average | |||

| Thickness (minimum average), mm minimum, mm | ASTMD 5994 | per volume | 1.0 0.9 | 1.50 1.35 | 2.0 1.8 | 2.50 2.25 |

| Density, g/cm³ | ASTMD792/D 1505 | Every five volumes | 0.94 | 0.94 | 0.94 | 0.94 |

| Tensile properties, (longitudinal and transverse) Crack strength, N/mm Yield strength, N/mm Elongation at break, % Elongation at yield, % | ASTMD6693, Category IV Dumbbell shaped, 2 ipm G1.51 mm GL.33 mm | Every five volumes | 24 15 600 13 | 37 23 600 13 | 48 30 600 13 | 60 38 600 13 |

| Resistant to right-angle tears, N | ASTMD1004 | Every five volumes | 125 | 187 | 249 | 311 |

| Puncture resistance, N | ASTMD4833 | Every five volumes | 352 | 530 | 703 | 881 |

| Carbon Black Content, % | ASTMD1603/D4218 | Every five volumes | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

| Carbon black distribution | ASTMD5596 | Every five volumes | Note 4 | Note 0 | Note 4 | Note 0 |

| Rough height 0,mm | ASTMD7466 | Every two volumes | 0.25 | 0.25 | 0.25 | 0.25 |

| Resistant to environmental stress cracking (Incision dead-load tensile method) HRS | ASTMD5397, Appendix | 90,000kg | 400 | 400 | 400 | 400 |

| Oxidation induction time, mins or High-pressure oxidation induction time, mins | ASTMD3895,200°C;0,1 atm ASTMD5885,150C; O 3.4 MPa | 90,000kg | >100 >400 | >100 >400 | >100 >400 | >100 >400 |

| 85°C oven aging Oxidation induction time - retention after 90 days; or Autoclavic oxidation induction time - retention after 90 days | ASTMD5721 ASTMD 3895 ASTMD5885 | per recipe | 55% 80% | 55% 80% | 55% 80% | 55% 80% |

| UV resistance Autoclave oxidation induction time - retention after 1600 h | ASTMD7238 ASTMD5885 | per recipe | 50% | 50% | 50% | 50% |

| Gauge size of standard film rolls | ||||||

| Spring Length, m | 200 | 100 | 80 | 60 | ||

| Roll width, m | 8.0 | 8.0 | 8.0 | 8.0 | ||

| Roll area, m² | 1.600 | 800 | 640 | 480 | ||

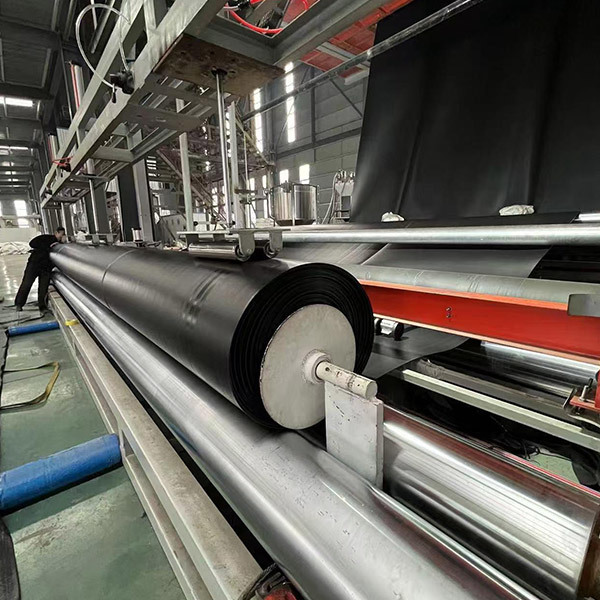

Factory appearance

Shandong Xinying New Materials Co., Ltd. will be strong economic and technical strength, excellent product quality, casting China geo building materials new brand new image.

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products