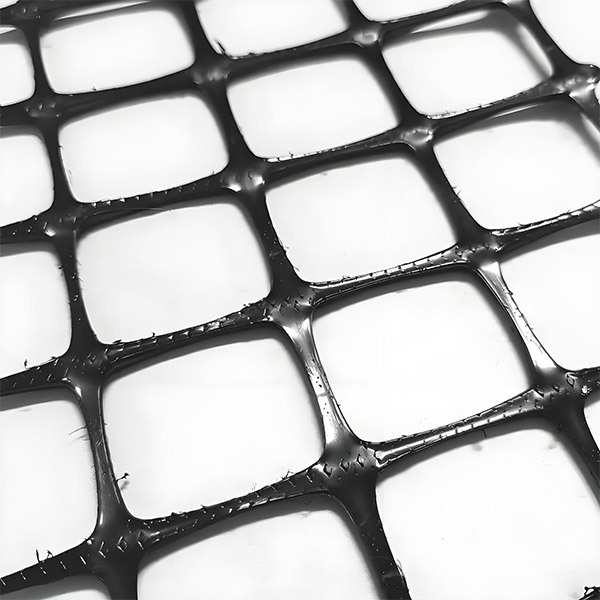

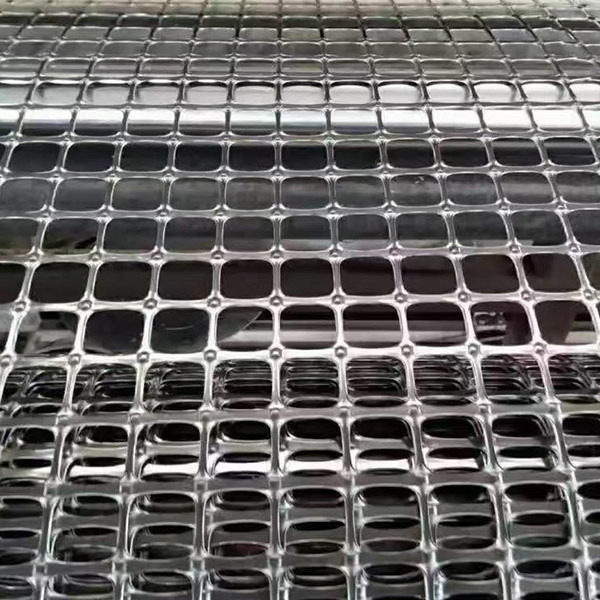

Bi-directional Plastic Stretch Geogrid

- Commodity name: Bi-directional Plastic Stretch Geogrid

Keyword:

Bi-directional Plastic Stretch Geogrid

- PRODUCT DESCRIPTION

-

The two-way plastic geogrid is made of polymer through the process of extrusion, plate forming and punching, and then stretched longitudinally and transversely. The material has great tensile strength in both longitudinal and transverse directions, and this structure can also provide an ideal interlocking system for more effective force bearing and diffusion in the soil, suitable for large-area permanent bearing of foundation reinforcement.

peculiarity

1. Bidirectional tensile performance: The bidirectional geogrid has high tensile strength and stiffness, which can evenly distribute the load in both directions and improve the bearing capacity and stability of the soil.

2. High chemical resistance: The two-way geogrid has good chemical resistance, and can be used for a long time in acid-alkali environments without chemical corrosion.

3. Strong durability: The two-way geogrid has good durability, which can resist the effects of ultraviolet rays, oxidation and aging for a long time, and maintain its mechanical properties and service life.

4. Good permeability: The two-way geogrid has a certain permeability, which can allow the water in the soil to pass through, preventing water accumulation and soil liquefaction

use

Biaxially oriented plastic geogrid is suitable for all kinds of embankment and subgrade reinforcement, slope protection, cave wall reinforcement, large airports, parking lots, wharves and freight yards and other permanent bearing foundation reinforcement.

1. The two-way geogrid is used to increase the bearing capacity of the road (ground) foundation and prolong the service life of the road (ground) foundation.

2. The two-way geogrid is used to prevent the road (ground) surface from collapsing or cracking, and keep the ground beautiful and tidy.

3. The two-way geogrid is used for convenient construction, time-saving, labor-saving, shortening the construction period and reducing maintenance costs.

4. Two-way geogrid is used to prevent cracks in the culvert.

5. Two-way geogrid is used to strengthen the soil slope and prevent soil erosion.

6. Two-way geogrid is used to reduce the thickness of the cushion and save the cost.

7. The two-way geogrid is used to support the stability of the slope grass planting net mat and the green environment.Construction method

When used for roadbed, pavement, excavate the foundation bed, set up a sand cushion (height difference is not more than 10cm), roll into a platform, lay the grid, the longitudinal axial direction should be consistent with the main force direction, longitudinal lap 15-20cm, transverse 10cm, lap joint with plastic tape binding, and on the laid grid, every 1.5-2m with U-nails fixed on the ground, the laid geogrid should be backfilled in time, and the number of layers of the laid geogrid depends on the technical requirements.When used for reinforced earth retaining walls, the construction is issued as follows:

Set the foundation, according to the design of the wall system construction, when the prefabricated reinforced concrete panel is selected, the general thickness of 12-15cm support on the precast concrete foundation. Its width is not more than 30cm, the thickness is not less than 20cm, and the buried depth is not less than 60cm to prevent the impact of frost heaving of the foundation;

Flatten the wall foundation, excavate and level according to the design requirements. The soft soil needs to be compacted or replaced, compacted to the required density, which should slightly exceed the scope of the wall;

When the reinforcement is laid, the main strength direction of the reinforcement should be perpendicular to the wall and fixed with pins;

The wall is filled with mechanical soil, and the distance between the wheel and the reinforcement should be kept at least 15cm, and the thickness of a layer of soil after compaction is about 15-20cm;

During wall construction, the wall should be covered with geotextiles to prevent the leakage of filling.

Project/TGSG 1515 2020 2525 3030 3535 4040 4545 5050 Longitudinal tensile yield force per linear meter 15 20 25 30 35 40 45 50 Tensile force at 2% elongation in the longitudinal and horizontal directions 5 7 9 10.5 12 14 16 17.5 Tensile force at 5% elongation in the longitudinal and horizontal directions 7 14 17 21 24 28 32 35 Longitudinal yield elongation %≤ 15 Transverse yield elongation %≤ 13 Width (m) 1-6 remark Special specifications, produced in accordance with the requirements of the contract or agreement

Factory appearance

Shandong Xinying New Materials Co., Ltd. will be strong economic and technical strength, excellent product quality, casting China geo building materials new brand new image.

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products