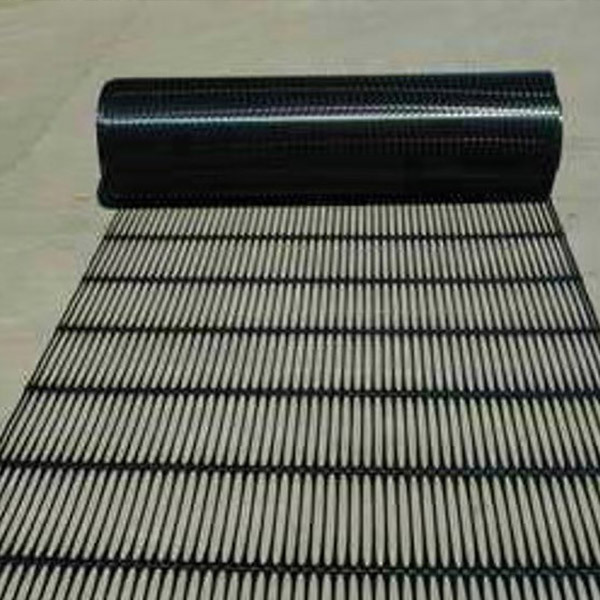

One-way Plastic Geogrid

- Commodity name: One-way Plastic Geogrid

Keyword:

One-way Plastic Geogrid

- PRODUCT DESCRIPTION

-

Unidirectional stretching geogrid is a kind of high-strength geotechnical material with polymer as the main raw material, adding certain anti-ultraviolet and anti-aging additives, reorienting and arranging the original scattered chain molecules in a linear state through unidirectional stretching, pressing into a thin plate and then punching the regular hole net, and then stretching longitudinally. In this process, the polymer is formed into a directional linear state and forms an oblong elliptical network monolithic structure with uniform distribution and high node strength.

Brief introduction

This structure has quite high tensile strength and tensile modulus, tensile strength reaches 100-200Mpa, close to the level of low carbon steel, much better than the traditional or existing reinforced materials, especially such products have more than the international level of high early (elongation in 2%-5%) tensile strength and tensile modulus. It provides the soil with an ideal interlocking system for the bearing and diffusion of force. The product has high tensile strength (>150Mpa), adapts to various soils, and is a widely used reinforcement material. Its main characteristics are: high tensile strength, good creep performance, convenient construction and low price.Constituent materials

Unidirectional geogrid is made of polymer (PP or HDPE) extruded and pressed into a thin plate, then punched into a regular hole mesh, and then stretched longitudinally. In this process, the polymer is formed into a directional linear state and forms an oblong elliptical network monolithic structure with uniform distribution and high node strength.Main uses:

1. One-way geogrid is used to strengthen weak foundations: geogrids can quickly improve the bearing capacity of the foundation, control the development of settlement, and effectively distribute the load to a wider subbase layer by limiting the lateral effect on the road base, thereby reducing the thickness of the base, reducing the project cost, shortening the construction period, and prolonging the service life.

2. One-way geogrid is used for reinforced asphalt or cement pavement: the geogrid is laid at the bottom of the asphalt or cement pavement, which can reduce the rutting depth, prolong the fatigue life of the pavement, and also reduce the thickness of the asphalt or cement pavement to save costs.

3. One-way geogrid is used to reinforce embankment slope and retaining wall: the filling of traditional embankment, especially high embankment, often needs to be overfilled and the edge of the shoulder is not easy to compact, which leads to the rainwater flooding of the slope in the later stage, and the phenomenon of collapse and instability occurs from time to time, and the slower slope needs to be used at the same time, the area is large, and the retaining wall also has the same problem, and the use of geogrid to reinforce the embankment slope or retaining wall can reduce the floor area by one-third, prolong the service life, and reduce the cost by 20-50%.

4. One-way geogrid is used to strengthen river seawalls: it can be made into gabion, and then used in conjunction with the grid to prevent the dam from collapsing caused by seawater, and the gabion has permeability, which can slow down the impact of waves, prolong the life of the embankment, save manpower and material resources, and shorten the construction period.

5. One-way geogrid is used to treat landfills: geogrids are used in combination with other soil synthetic materials to treat landfills, which can effectively solve the problems of uneven settlement of the foundation and derived gas emissions, and can maximize the storage capacity of the landfill.

6. Special use of unidirectional geogrid: low temperature resistance. After 200 times of repeated cold and heat cycles at -45 °C --— 50 °C, all performance indicators meet the requirements and have been tested by the Qinghai-Tibet Railway, which is suitable for the poor geology of less frozen soil, rich frozen soil and high ice content frozen soil in the north.Construction method

When used for roadbed and pavement, the construction method is the same as that of two-way geogrid.

Excavate the foundation bed, set up a sand cushion (height difference is not more than 10cm), roll into a platform, lay a grid, the longitudinal axial direction should be consistent with the main force direction, longitudinal lap 15-20cm, transverse 10cm, lap with plastic tape binding, and on the laid grid, every 1.5-2m with U-shaped nails fixed on the ground, the laid geogrid should be backfilled in time, and the number of layers of the laid geogrid depends on the technical requirements.

When used for reinforced earth retaining walls, the construction method is as follows:

1. Set up the foundation, carry out construction according to the designed wall system, and when the prefabricated reinforced concrete panel is selected, the general thickness of 12-15cm is supported on the precast concrete foundation. Its width is not more than 30cm, the thickness is not less than 20cm, and the buried depth is not less than 60cm to prevent the impact of frost heave of the foundation.

2. Smooth the wall foundation, excavate and level according to the design requirements. The soft soil needs to be compacted or replaced, compacted to the required density, which should slightly exceed the scope of the wall.

3. The main strength direction of the reinforcement should be perpendicular to the wall and fixed with pins.

4. The wall is filled with mechanical filling, and the distance between the wheels and the reinforcement should be kept at least 15cm. After compaction, the thickness of a layer of soil is about 20-15cm.

5. During wall construction, the wall should be covered with geotextiles to prevent the leakage of filling.Technical parameters of polypropylene (PP) unidirectionally stretched plastic geogrid

Item/Specification TGDG35 TGDG50 TGDG80 TGDG120 TGDG160 TGDG200 Tensile yield force per linear meter 35 50 80 120 160 200 Elongation at yield 10 Tensile force at 2% elongation 10 12 26 36 45 56 Tensile force at 5% elongation 22 28 48 72 90 112 Ultimate creep strength 15 21 30.2 41 49 64 Technical parameters of polyethylene (PE) unidirectional stretch plastic geogrid

Item/Specification TGDG35 TGDG50 TGDG80 TGDG120 TGDG160 TGDG200 Tensile yield force per linear meter 35 50 80 120 160 160 Elongation at yield 10 Tensile force at 2% elongation 7.5 12 21 33 33 47 Tensile force at 5% elongation 21.5 23 40 65 65 93 Ultimate creep strength 16 21 31 46 46 60

Factory appearance

Shandong Xinying New Materials Co., Ltd. will be strong economic and technical strength, excellent product quality, casting China geo building materials new brand new image.

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products