EPI Geomembrane vs. Traditional Waterproofing Solutions: A Comprehensive Guide

Time:

May 23,2025

EPI Geomembrane vs. Traditional Waterproofing Solutions: An In-Depth Analysis Waterproofing is a vital process in construction and landscaping, ensuring structures remain intact and free from moisture-related damage. The choice of waterproofing method can significantly impact the longevity and integrity of a project. In recent years, EPI geomembranes have emerged as a popular choice, leading to co

EPI Geomembrane vs. Traditional Waterproofing Solutions: An In-Depth Analysis

Waterproofing is a vital process in construction and landscaping, ensuring structures remain intact and free from moisture-related damage. The choice of waterproofing method can significantly impact the longevity and integrity of a project. In recent years, EPI geomembranes have emerged as a popular choice, leading to comparisons with traditional waterproofing solutions. This article aims to provide a detailed examination of EPI geomembranes and how they contrast with conventional methods.

Table of Contents

- 1. Introduction to Waterproofing Solutions

- 2. Understanding EPI Geomembranes

- 3. Traditional Waterproofing Solutions

- 4. EPI Geomembrane vs. Traditional Waterproofing: A Comparative Analysis

- 5. Applications of EPI Geomembranes and Traditional Solutions

- 6. Installation Procedures

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Waterproofing Solutions

In the construction industry, **waterproofing** serves as a defense mechanism against water infiltration, which can lead to structural damage, mold growth, and aesthetic issues. Various traditional solutions, including **bituminous coatings**, **liquid-applied membranes**, and **cementitious materials**, have been historically used to safeguard buildings and landscapes. However, the emergence of newer materials like **EPI geomembranes** has sparked a discussion about the efficiency, effectiveness, and environmental implications of different waterproofing methods.

2. Understanding EPI Geomembranes

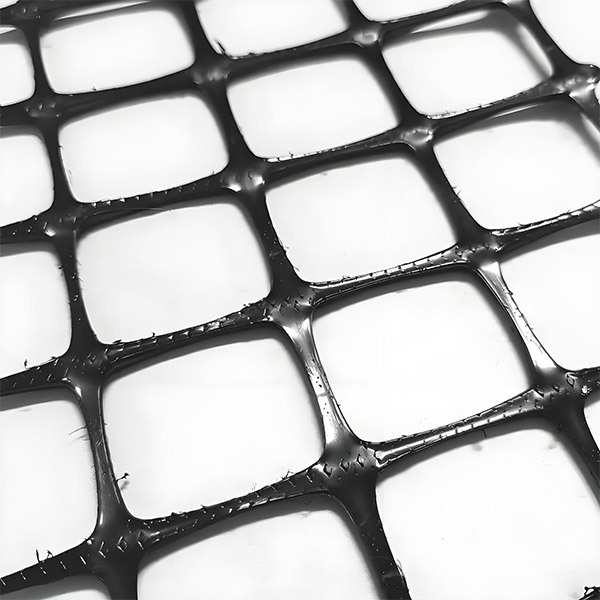

EPI geomembranes are synthetic membranes made from high-density polyethylene (HDPE) or other durable polymers. They provide an impermeable barrier that is utilized in various applications, including landfills, water reservoirs, and environmental protection projects.

2.1 Composition and Manufacturing Process

EPI geomembranes consist of specially formulated resins that enhance their mechanical properties, making them both flexible and durable. The manufacturing process involves extrusion or calendering techniques, ensuring that the membranes are uniform and free from defects. The high-quality production standards contribute to their long lifespan and resistance to environmental stressors.

2.2 Advantages of EPI Geomembranes

The benefits of EPI geomembranes include:

- **Superior Durability**: EPI geomembranes exhibit high resistance to punctures, tears, and environmental factors such as UV radiation.

- **Chemical Resistance**: They are resistant to a wide range of chemicals, making them suitable for use in industrial applications and landfills.

- **Low Permeability**: EPI geomembranes provide an impermeable barrier against water and leachate, ensuring effective containment.

- **Ease of Installation**: The lightweight nature of geomembranes allows for quick and efficient installation, reducing labor costs.

3. Traditional Waterproofing Solutions

Traditional waterproofing solutions typically involve several methods that rely on various materials and techniques to prevent water ingress.

3.1 Types of Traditional Waterproofing Solutions

The most common traditional waterproofing solutions include:

- **Bituminous Coatings**: These are commonly used for roofs, providing a waterproof layer through asphalt-based products.

- **Liquid-Applied Membranes**: These involve applying a liquid polymer that cures to form a seamless waterproof barrier.

- **Cementitious Waterproofing**: This technique uses cement-based products that can be applied to surfaces to provide moisture protection.

3.2 Limitations of Traditional Methods

Despite their long-standing application, traditional waterproofing solutions have several limitations:

- **Shorter Lifespan**: Many traditional methods have a limited lifespan, often requiring frequent repairs or replacements.

- **Environmental Concerns**: Some traditional materials contain harmful chemicals that may pose environmental risks during installation and application.

- **Labor-Intensive**: The installation of traditional waterproofing solutions can be labor-intensive and time-consuming, resulting in higher overall costs.

4. EPI Geomembrane vs. Traditional Waterproofing: A Comparative Analysis

When choosing between EPI geomembranes and traditional waterproofing methods, several factors come into play.

4.1 Cost-Effectiveness

While traditional methods might have lower upfront costs, their shorter lifespan and higher maintenance requirements can lead to increased lifecycle costs. In contrast, EPI geomembranes, although initially more expensive, offer more extended periods of durability and less maintenance, making them a more cost-effective option in the long run.

4.2 Durability and Longevity

EPI geomembranes are engineered for longevity, often lasting over 30 years without significant degradation. Traditional solutions, however, may require replacement or repair within 10 to 15 years, leading to continued investment in maintenance and repairs.

4.3 Environmental Impact

EPI geomembranes are designed with environmental safety in mind, often made from recyclable materials and posing minimal risk to surrounding ecosystems. In comparison, traditional waterproofing solutions may involve harmful chemicals and substances that can leach into the environment, raising concerns about their sustainability.

5. Applications of EPI Geomembranes and Traditional Solutions

EPI geomembranes are widely used in various applications, including:

- **Landfill Liners**: Their impermeability makes them ideal for waste containment.

- **Water Reservoirs**: They ensure clean water remains free from contaminants.

- **Environmental Remediation**: Used to contain hazardous materials during clean-up processes.

Traditional waterproofing methods find applications in:

- **Residential Roofing**: Bituminous coatings are often applied on flat roofs.

- **Basements**: Liquid-applied membranes protect below-ground structures from moisture ingress.

- **Bridge Decks**: Cementitious waterproofing is used to protect infrastructures from water damage.

6. Installation Procedures

The installation process for EPI geomembranes is typically straightforward, involving site preparation, deployment, and welding of seams to create a continuous barrier. Furthermore, the lightweight nature of geomembranes allows for quicker installation, minimizing labor costs.

In contrast, traditional waterproofing methods often require extensive preparation, application of multiple layers, and curing time, which can slow down the project timeline.

7. Frequently Asked Questions

**Q1: What is the primary difference between EPI geomembranes and traditional waterproofing solutions?**

A1: The primary difference lies in their material composition and durability. EPI geomembranes are synthetic, offering superior longevity and impermeability compared to traditional methods.

**Q2: Are EPI geomembranes environmentally friendly?**

A2: Yes, EPI geomembranes are designed to be environmentally safe, often made from recyclable materials and minimizing harmful leachate.

**Q3: How long do EPI geomembranes last?**

A3: EPI geomembranes can last over 30 years with minimal maintenance, compared to traditional methods, which typically last 10-15 years.

**Q4: What types of projects benefit from EPI geomembranes?**

A4: EPI geomembranes are ideal for landfills, water reservoirs, and any project requiring effective moisture barrier systems.

**Q5: Can traditional waterproofing methods be used in place of geomembranes?**

A5: While they can be used, traditional methods often come with higher maintenance costs and a shorter lifespan compared to EPI geomembranes.

8. Conclusion

In the ongoing battle between EPI geomembranes and traditional waterproofing solutions, it is clear that each method has its strengths and weaknesses. However, the **long-term durability**, **cost-effectiveness**, and **environmental safety** of EPI geomembranes make them a compelling choice for modern construction and landscaping projects. By understanding the differences and specific applications of each option, stakeholders can make informed decisions that enhance the sustainability and integrity of their projects.