How to Choose the Right Composite Geomembrane for Your Project: A Comprehensive Guide

Time:

May 03,2025

How to Choose the Right Composite Geomembrane for Your Project Selecting the right composite geomembrane for your project is crucial for ensuring durability, efficiency, and cost-effectiveness. Composite geomembranes serve a variety of purposes in construction—from environmental protection to structural integrity. In this guide, we'll delve into the essential aspects of choosing the right composit

How to Choose the Right Composite Geomembrane for Your Project

Selecting the right composite geomembrane for your project is crucial for ensuring durability, efficiency, and cost-effectiveness. Composite geomembranes serve a variety of purposes in construction—from environmental protection to structural integrity. In this guide, we'll delve into the essential aspects of choosing the right composite geomembrane, providing you with a comprehensive approach to making an informed decision.

Table of Contents

- Understanding Composite Geomembranes

- Types of Composite Geomembranes

- Factors to Consider When Choosing Composite Geomembranes

- Application Areas for Composite Geomembranes

- Installation Process of Composite Geomembranes

- Maintenance and Care for Composite Geomembranes

- Cost Considerations for Composite Geomembranes

- Frequently Asked Questions

Understanding Composite Geomembranes

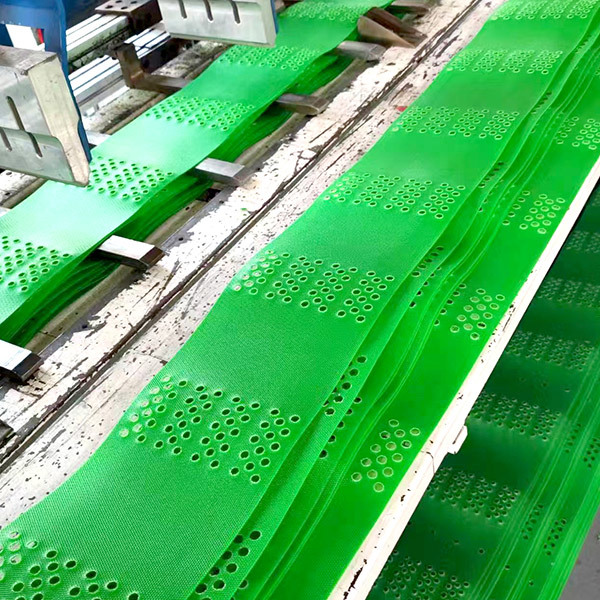

Composite geomembranes are engineered polymer sheets, typically consisting of a combination of materials—usually a flexible synthetic liner and a geotextile. They are designed to provide a barrier against liquids and gases, making them ideal for various applications such as landfills, mining operations, and water reservoirs.

These geomembranes offer enhanced durability and stability compared to single-layer liners, thanks to their multi-layer construction. Their unique properties allow for better resistance to punctures, UV degradation, and chemical exposure.

Types of Composite Geomembranes

When selecting a composite geomembrane, it’s crucial to understand the different types available on the market:

Polyethylene Composite Geomembranes

Polyethylene composite geomembranes are widely used due to their excellent chemical resistance and flexibility. They are ideal for applications involving water containment or exposure to harsh chemicals.

Polypropylene Composite Geomembranes

Polypropylene materials are known for their strength and resistance to UV light. They are suitable for applications that require a high degree of durability and performance under extreme weather conditions.

PVC Composite Geomembranes

Polyvinyl chloride (PVC) geomembranes offer a good balance of flexibility and chemical resistance, often used in applications like waste containment and aquaculture.

Factors Influencing the Choice of Composite Geomembranes

1. **Chemical Compatibility**: Ensure the geomembrane material can withstand the chemicals it will be exposed to in its intended application.

2. **Thickness and Tensile Strength**: Thicker membranes offer greater puncture resistance, which is crucial for landfill or mining applications.

3. **Environmental Conditions**: Assess the temperature ranges, UV exposure, and weather conditions that the geomembrane will encounter.

Factors to Consider When Choosing Composite Geomembranes

Choosing the right composite geomembrane involves several critical factors:

Project Specifications

Understand the specific requirements of your project, including load-bearing capacities, environmental regulations, and site characteristics.

Durability and Longevity

Evaluate the expected lifespan of the geomembrane under typical conditions. Choose materials known for their long-term performance and stability.

Ease of Installation

Select a geomembrane that is not only effective but also easy to install. This can significantly reduce labor costs and installation time.

Environmental Impact

Consider the ecological footprint of the geomembrane material. Look for options that meet environmental standards and sustainability goals.

Application Areas for Composite Geomembranes

Composite geomembranes are versatile and can be used effectively in various applications:

Landfills

They are widely utilized in landfill applications to prevent leachate from contaminating the surrounding soil and groundwater.

Wastewater Treatment

In wastewater treatment plants, composite geomembranes help contain liquids and manage effluent.

Mining Operations

Their chemical resistance makes them suitable for mining, where they protect against harmful substances.

Water Reservoirs

Composite geomembranes provide a reliable barrier for storing water in reservoirs, preventing leakage and contamination.

Installation Process of Composite Geomembranes

The installation of composite geomembranes requires careful planning and execution:

Site Preparation

Begin with thorough site preparation, ensuring the ground is level and free from debris that could damage the membrane.

Material Handling

Handle the geomembrane rolls with care to avoid tears or punctures.

Installation Techniques

Utilize appropriate techniques such as welding or adhesive bonding to secure the geomembranes in place, ensuring watertight seals.

Quality Assurance

Conduct necessary inspections during and after installation to confirm the integrity and effectiveness of the geomembrane.

Maintenance and Care for Composite Geomembranes

Regular maintenance is essential for extending the lifespan of composite geomembranes:

Routine Inspections

Schedule regular inspections to identify any potential damage or wear and tear that may need addressing.

Cleaning Protocols

Implement a cleaning routine to remove debris, algae, or any build-up that may affect the integrity of the geomembrane.

Immediate Repairs

Address any damage immediately, whether through patching or complete replacement, to prevent further issues.

Cost Considerations for Composite Geomembranes

Understanding the cost implications of composite geomembranes is vital for project budgeting:

Material Costs

The price of the geomembrane can vary significantly depending on the type and thickness. It’s essential to balance cost with quality for long-term performance.

Installation Costs

Consider both labor and equipment costs involved in the installation process. Opting for user-friendly materials may reduce installation expenses.

Maintenance Expenses

Account for ongoing maintenance costs, as a well-maintained geomembrane can save on future repairs and replacements.

Frequently Asked Questions

1. What is the lifespan of a composite geomembrane?

The lifespan can vary based on the material, environmental conditions, and maintenance efforts, typically ranging from 20 to 50 years.

2. How do I determine the right thickness for my project?

Choose thickness based on the specific requirements of your project, such as load-bearing capacities and exposure to potential damage.

3. Can composite geomembranes be recycled?

Many composite geomembranes have recycling options available, but it depends on the materials used. Check with the manufacturer for recycling information.

4. What are the most common installation methods for geomembranes?

Common installation methods include thermal welding, adhesive bonding, and mechanical fastening, depending on the project requirements.

5. How can I ensure the longevity of my composite geomembrane?

Regular inspections, proper maintenance, and immediate repairs are critical for extending the life of your geomembrane.

Conclusion

Choosing the right composite geomembrane for your project requires careful consideration of several factors, including material properties, cost, and application areas. By understanding the nuances of composite geomembranes and following best practices for selection and installation, you can safeguard your project’s success. Ensuring the integrity and performance of your geomembranes through proper maintenance will not only protect your investment but also contribute to the sustainability of your construction efforts.